Learn how OrthoSolid is replacing plaster casts and labor-intensive hand-layups with a simple scan-or-measurement workflow powered by Grasshopper and ShapeDiver.

Introduction

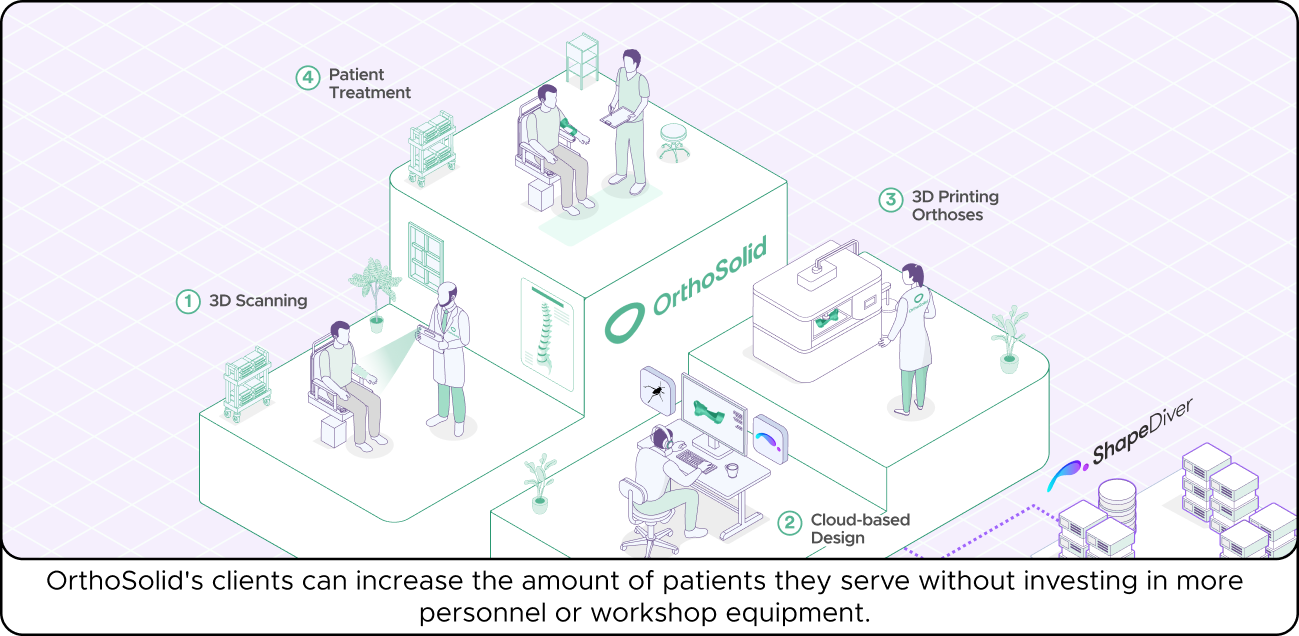

A few weeks ago, Orthobroker , a renowned Belgian supplier of prefabricated orthopedic products, launched OrthoSolid®. This ShapeDiver-powered online platform lets clinicians design and order fully custom orthoses and prostheses in a matter of minutes. By replacing plaster casts and labor-intensive hand-layups with a simple scan-or-measurement workflow, the cloud service guides users through annotation, automatic fit optimization, and accessory placement, all before a single part is printed. The result is a fast, repeatable process that preserves the craft knowledge of orthotists while unlocking the geometric freedom of additive manufacturing.

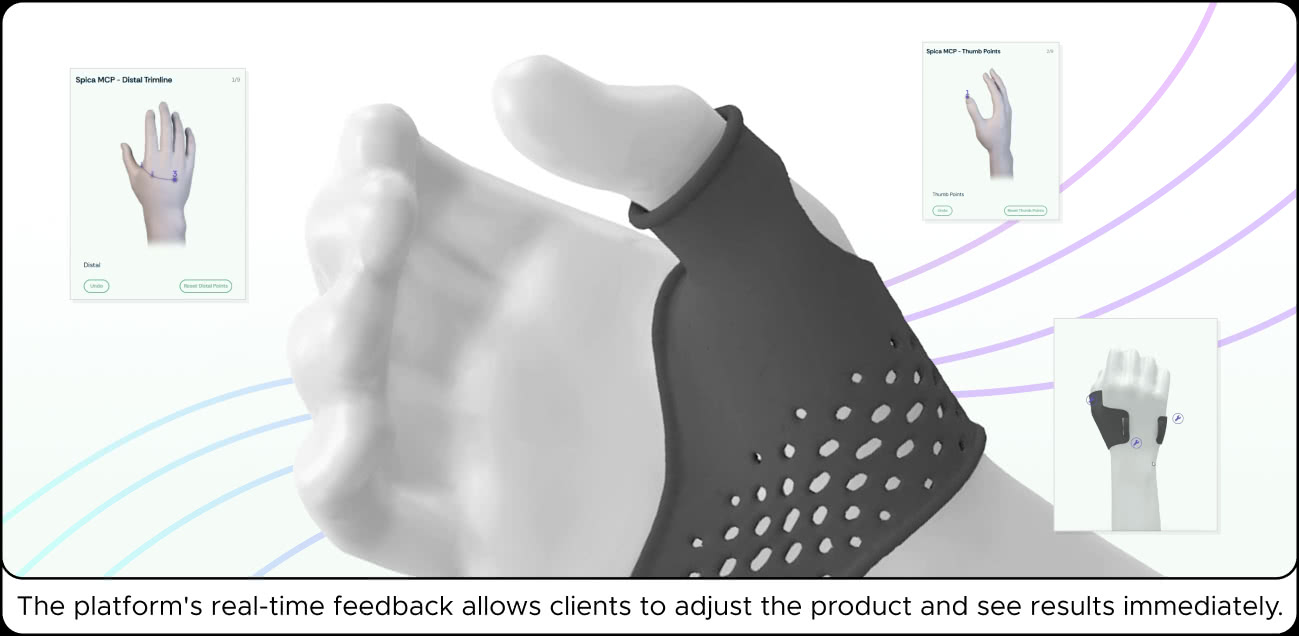

At the heart of this transformation is a Grasshopper-driven design engine. OrthoSolid’s product-specific scripts capture every clinical parameter of splints like Volar, Carpi, and the upcoming upper-limb line. Thanks to ShapeDiver, those Grasshopper scripts run in the cloud, feeding real-time 3D to any browser so technicians can instantly see the impact of their decisions without installing CAD or writing code.

Once a patient’s order is approved, designs go straight to OrthoSolid’s in‑house HP Multi Jet Fusion printers. The process produces lightweight, ventilated lattices that stay strong under daily load, shed moisture, and clean easily, advantages difficult to match with laminated thermoplastics. ISO‑certified workflows and step‑by‑step quality checks keep every print consistent, whether the order is for a single paediatric splint or a thousand units for a national provider.

For hospitals, O&P chains, and independent CPOs alike, the result is shorter lead times, fewer appointments, and a growth path that does not require hiring linearly with demand. With encrypted European hosting, role‑based permissions, and optional links to existing patient‑management systems, the fully online platform seamlessly integrates into current operations while opening the door to new, data‑driven services. And this is only the beginning: upper‑limb additions, new materials, and continuous UX refinements are already on the roadmap, ensuring that OrthoSolid stays a step ahead as digital orthotics becomes the standard of care.

This case study explores how the team behind OrthoSolid wove together custom medical-device know-how, parametric design, industrial 3D printing, and ShapeDiver’s scalable computing layer to deliver a platform that helps clinics treat more patients, with better outcomes and lower overhead. Whether you’re a medical professional evaluating digital workflows, a 3D-printing specialist seeking high-value applications, or a Grasshopper power-user curious about the medical field, the following interview reveals the possibilities and the lessons learned of taking orthotics online at scale. Let’s dive in!

1. Can you introduce the team behind OrthoSolid? What are their backgrounds, and how did their expertise in orthotics, computational design, and 3D printing shape the platform’s development?

Our team at OrthoSolid brings together a strong mix of expertise in orthotics, design, and technology. The company is led by founder Patrick Garmyn, who has many years of experience in orthopedic rehabilitation and the orthopedic medical device industry. He works closely with our sales and product management team, which includes orthopedic specialists.

Our product design engineers focus on creating effective solutions by combining their knowledge of product design, parametric modeling (using Grasshopper), and user experience design for the platform.

Meanwhile, our software developers turn these ideas into a reliable and user-friendly platform.

Together, this blend of expertise and continuous feedback from our clients drives OrthoSolid's ongoing development and improvement.

2. What’s the story behind Orthobroker’s transition from a traditional prefab orthopedic supplier to launching OrthoSolid? How did the company identify the need to disrupt itself and embrace a digital-first approach?

Orthobroker has a history as a supplier of prefabricated orthopedic products, with its successful BraceID® brand. When Orthobroker hired its first product developer, interest in 3D printing followed.

This shift opened new possibilities for customized, patient-specific solutions that conventional manufacturing methods couldn’t fully address. OrthoSolid was developed to bridge the gap between traditional workflows and digital manufacturing, offering a more accessible, scalable platform for custom product creation.

The OrthoSolid® brand now exists in parallel with BraceID®, giving it a secure foundation to enter the market.

3. How does OrthoSolid leverage computational design to streamline the creation of custom orthotics like Volar, Mino, and Carpi? What specific advantages does this offer over traditional manual methods?

Digital product designs offer a great way to create complex designs with minimal effort. Starting with a 3D scan instead of a cast (which in itself is a remarkable improvement), clients can achieve precise and repeatable results with minimal time investment, a crucial factor in a market where trained professionals are becoming more scarce.

Real-time feedback allows clients to adjust and see results immediately, meaning they can fine-tune designs more effectively without time penalties.

The platform also allows our and our customers' businesses to grow without having to increase employee count linearly, meaning scale will be to our advantage.

4. Why was Grasshopper chosen for OrthoSolid’s design scripts? How does it enhance precision and flexibility in tailoring orthotics to individual patient measurements?

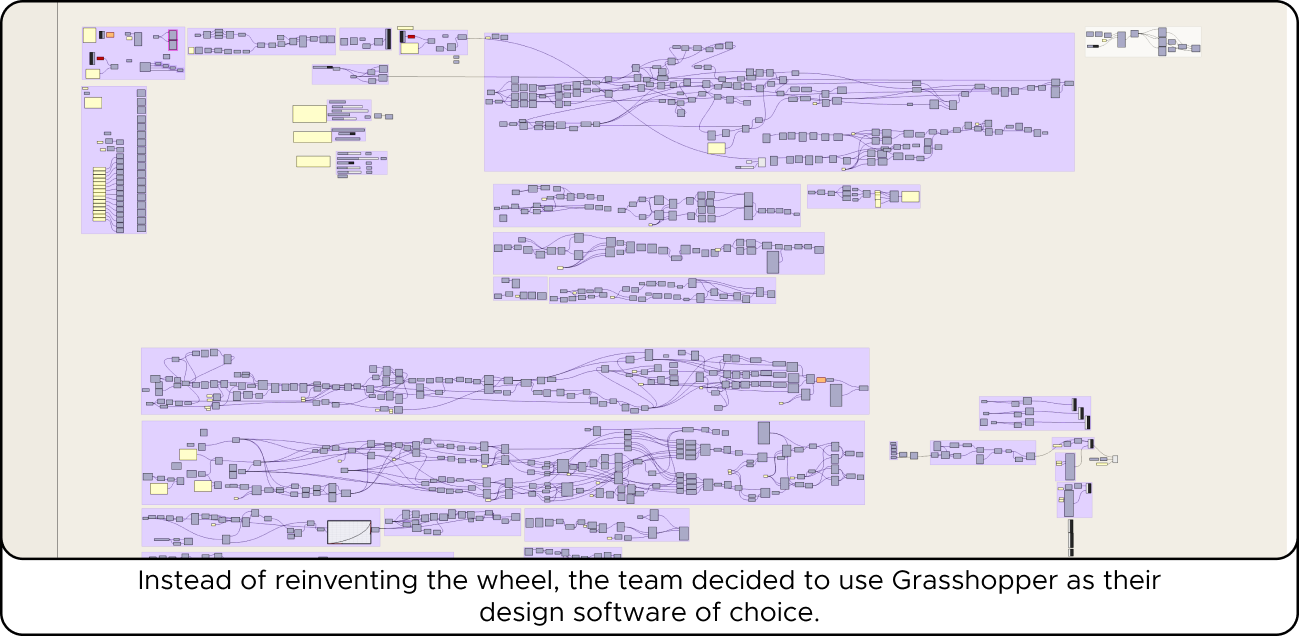

Having tried (and failed) to create products with morphing technology, a more precise and flexible option was needed.

As we have a product-first vision, we did not want to create a general ‘CAD’ system. We need precise control of product features and custom controllable features for clients.

Grasshopper allows this quite well, and it allows us to quickly iterate without complex software overhead.

5. How does 3D printing improve the production of orthotics compared to conventional manufacturing? What benefits stand out, like durability, lightweight design, or customization?

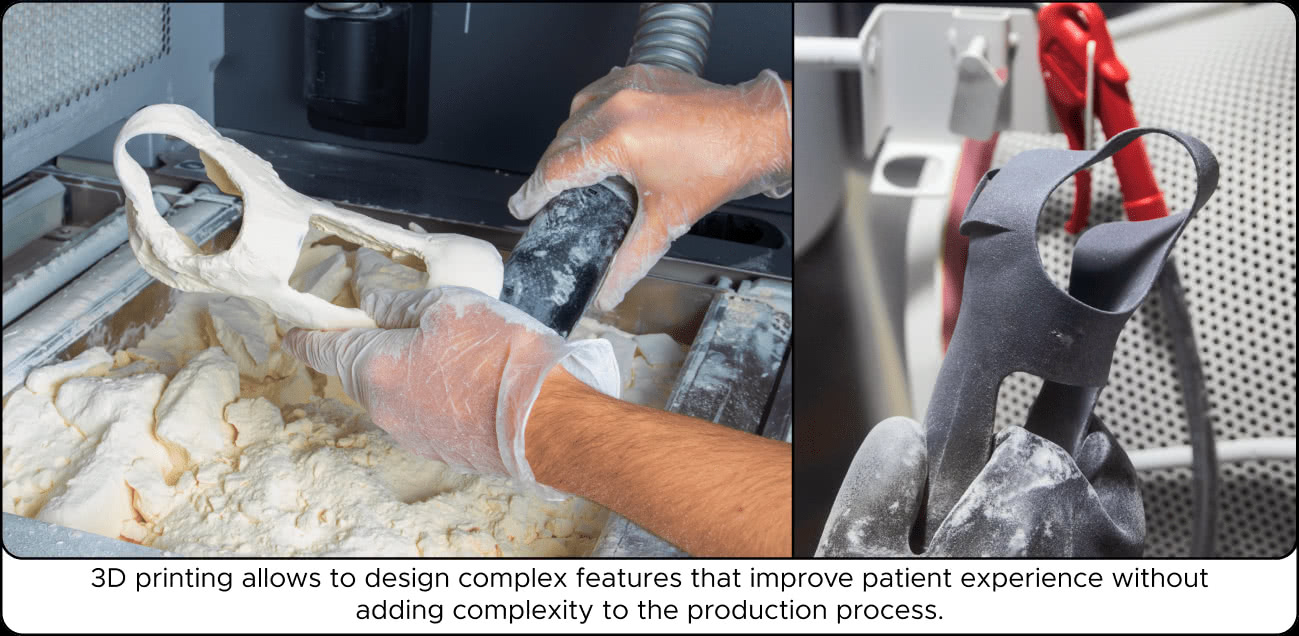

HP Multi Jet Fusion printing's main enabler is its design freedom. We can design complex features that improve patient experience without adding complexity to the production process. This means we and our clients can focus more on the patient.

Our materials are durable, skin-safe, and look good when printed.

6. How does ShapeDiver support OrthoSolid’s online customization platform? What role does it play in making the process intuitive for orthopedic technicians adjusting features like trimlines or joint angles?

ShapeDiver is the crucial link between our designs and our clients. We cannot see OrthoSolid working without the real-time feedback that ShapeDiver allows us to provide for our clients.

We can and do create custom product flows easily, only limited by what is possible in Grasshopper.

7. Your end-to-end digital platform integrates 3D scanning, cloud-based design, and direct manufacturing. How does this improve efficiency for orthopedic technicians and clinics?

In the right business cases, our services save considerable time.

Saving time on casting and a complex traditional product creation reveals the opportunity to serve more patients while keeping quality consistent due to our validated flow.

Clients can increase the number of patients they serve without investing in more personnel or workshop equipment.

Win, win.

8. What are the impacts on lead times, costs, and scalability for larger healthcare providers?

Scale will bring the cost of our products down considerably. These savings can also eventually be passed on to our clients.

Thus, larger companies are a great fit for OrthoSolid since they only need a training investment to expand their business with quality devices at a good price and short lead times.

9. How does OrthoSolid ensure a smooth shift for technicians moving from traditional workflows to digital tools, especially with products like Volar requiring only measurements instead of casts or scans?

Transferring years of knowledge and experience into the digital world requires time and effort. Just as it did to learn their current workflows.

We know this and offer ample training and support for as long as our clients need it.

While initially steep, the learning curve quickly plateaus. Users start to notice the control they have over the product design, and they begin to apply it with confidence.

10. How does OrthoSolid maintain ISO-certified quality and safety standards with in-house 3D printing? What specific controls are in place to ensure consistency across high-volume production?

Our ISO certificates tell our clients that we have validated reliable processes during production. Our scripts are validated, and the production flow is set up with fixed procedures, with quality inspection at every step.

11. Can OrthoSolid scale to meet the needs of large medical companies producing thousands of orthotics?

Yes. In fact, OrthoSolid enables a new magnitude in scale and efficiency, which was previously impossible to achieve.

Due to the guided product flows with fail saves, both large and small teams can now achieve higher output while spending less time per product.

12. How does the platform handle increased demand without compromising quality?

Product quality remains consistent due to our ISO production flow, which is set up for large-scale operation.

13. How does OrthoSolid integrate with existing workflows in large organizations? Is it compatible with common industry tools for patient management or manufacturing?

OrthoSolid aims to lower the threshold to digitalization, but simply providing an intuitive platform isn’t enough.

True integration means adapting to existing workflows through versatility. We created a system of configurable roles and permissions that aligns with diverse organizational structures and while the platform includes a patient management system, its use is optional.

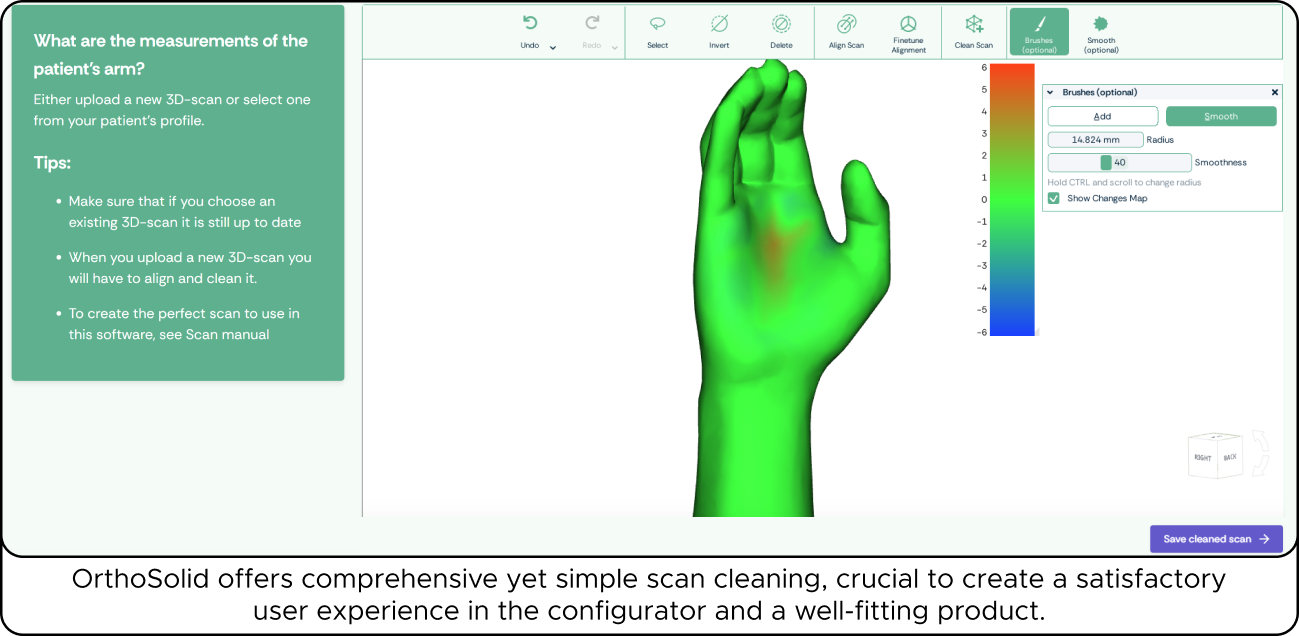

OrthoSolid also includes robust scan cleaning tools so that we can allow 3D-scans from all 3D scanners on the market.

14. What safeguards does OrthoSolid implement to protect patient data in its cloud-based platform, especially given the sensitivity of medical information for large-scale clients?

First off, we minimise the data required to create a product. Data that is needed, is encrypted in a way so that only the professional has access to it. Only when support from our side is needed, client give explicit confirmation for us to see their data.

Built from scratch, OrthoSolid uses the latest authentication and storage services together with European servers.

15. What’s next for OrthoSolid? Are there plans to expand features, like new materials, additional orthotic designs, or enhanced cloud capabilities, to further serve the industry?

While the platform is launched and being used as it is, we’re not planning on standing still.

Product range expansion is key for the success of OrthoSolid. First up is to complete our upper limb solutions.Next, we’ll move on to other product groups.

While working on those, ongoing user feedback will translate to smaller updates, improving the ease of use.

- Excellent! Congratulations on the launch, and thank you for your time during this interview.

Thank you as well for the opportunity to share our story.

That's it for this new edition of Getting to know... Don't forget to visit OrthoSolid's website!

Would you like to get featured in this space? Please email us at contact@shapediver.com and tell us about your project or brand! We'd love to start a conversation.