Dive into the dynamic world of industrial design in this interview with a footwear designer from Chile who has made his mark in the world by leveraging technology and materials to enhance the form and function of shoes.

With a career that has taken him from Chile to Holland and now Germany, he shares his journey from being inspired by Italian ads as an '80s child to becoming a leading expert in footwear design and production technology.

Today, he's part of the Innovation department at framas, a leading producer of plastic components for the shoe industry. Learn about the role of Grasshopper and parametric design in footwear creation, the impact of additive manufacturing, the revolutionary use of lattice structures, and the future of the footwear industry as shaped by artificial intelligence, 3D printing, and sustainability.

Whether you're a designer, a technologist, or a footwear enthusiast, this interview offers fascinating insights into the intricate world of shoe design and the transformative power of technology in shaping the industry. Let's dive in!

1. Welcome, René! Please give us a brief introduction of yourself.

My name is René Medel. I am an industrial designer, and I come from Chile. I have been a Rhino user for many years and have been an authorized trainer since 2004. After doing a Master of Footwear Innovation (SLEM Holland), I came to Germany to work in footwear-related companies. I’ve always liked technology and computers, besides shoes, architecture, and design.

2. What are your first memories related to footwear design?

I remember a powerful ad on TV from an Italian brand that promoted the use of new soles made out of Polyurethane. As an 80’s child, it was easy to believe in the benefits of using those sneakers.

Same thing for those black school shoes with a traditional “commando” rubber outsole. As kids, we felt like we really got superpowers!

I clearly remember my sneakers with pegs on the heel. Interchangeable cylinders with different densities. And, of course, my first pair with that waffle outsole and its grip feeling. Many years after, I was lucky to meet Mike Friton, one of the innovators from that legendary innovation Kitchen where the waffles came from.

Another amazing and inspiring designer is Charles Bergman, who I met in the Netherlands to collaborate at the Dutch Design Week. Jan Jensen is another Dutch shoe designer who has made the most incredible and mind-blowing shoes. Another brand doing great shoe designs is United Nude, in collaboration with known architects and designers.

Nowadays, I am amazed by the talent and creation of Aldanondo y Fernandez, both architects, and shoemakers based in Barcelona. Ignacio and Catuxa make wonderful leather bespoke shoes with a carefully crafted technique.

3. When did you decide to start a career in footwear design, and why?

Shoes. It was my first thought when I searched for a subject for my bachelor's degree. Not only because it is an industrial product with several materials and fabrication processes but mainly because footwear is a dynamic industry that needs to be updated and improved using new technologies.

4. What is framas?

framas is the company I work for. It was founded in 1948 in Pirmasens, Germany. The first product framas produced were shoe lasts, which are still developed today at our German site. The company quickly expanded in the plastic processing industry and is nowadays one of the leading producers when it comes to plastic components for the shoe industry.

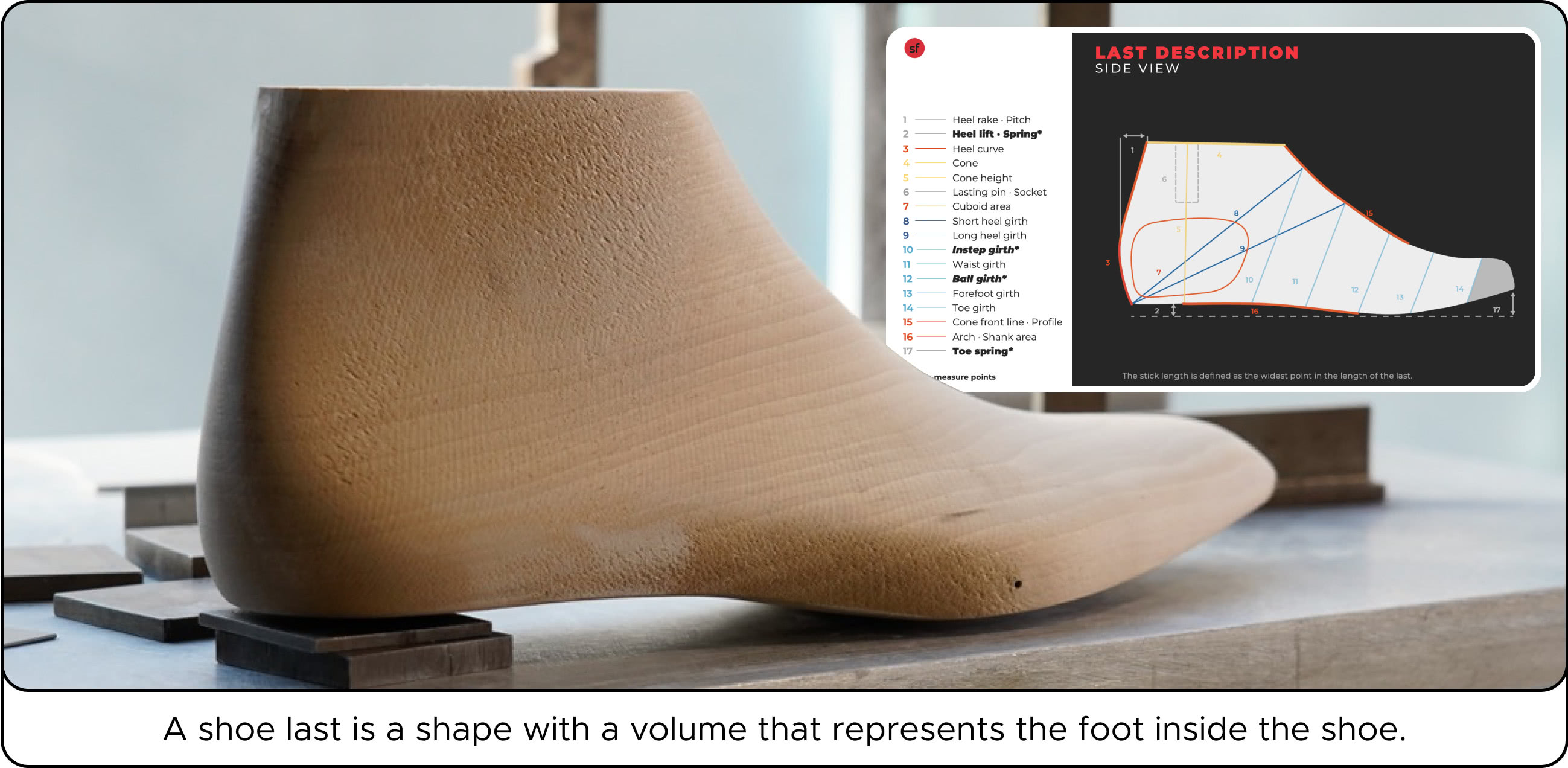

5. What are shoe lasts, and how are they traditionally manufactured?

A shoe last is a shape with a volume that represents the foot inside the shoe. It has the form of a shoe design and follows many dimensions and measures to ensure good fit and biomechanical features.

The base model (Master) is still made out of wood, but nowadays, the production is based on injected plastic which takes the shape after removing (CNC lathe) all the excess material.

6. What are your major responsibilities at framas?

My role in the Innovation department is to create workflows and 3D models to get the geometry of the products to be prototyped, analyzed, and produced among the group in our locations in Asia, besides our HQ in Germany.

7. When were you first introduced to Grasshopper?

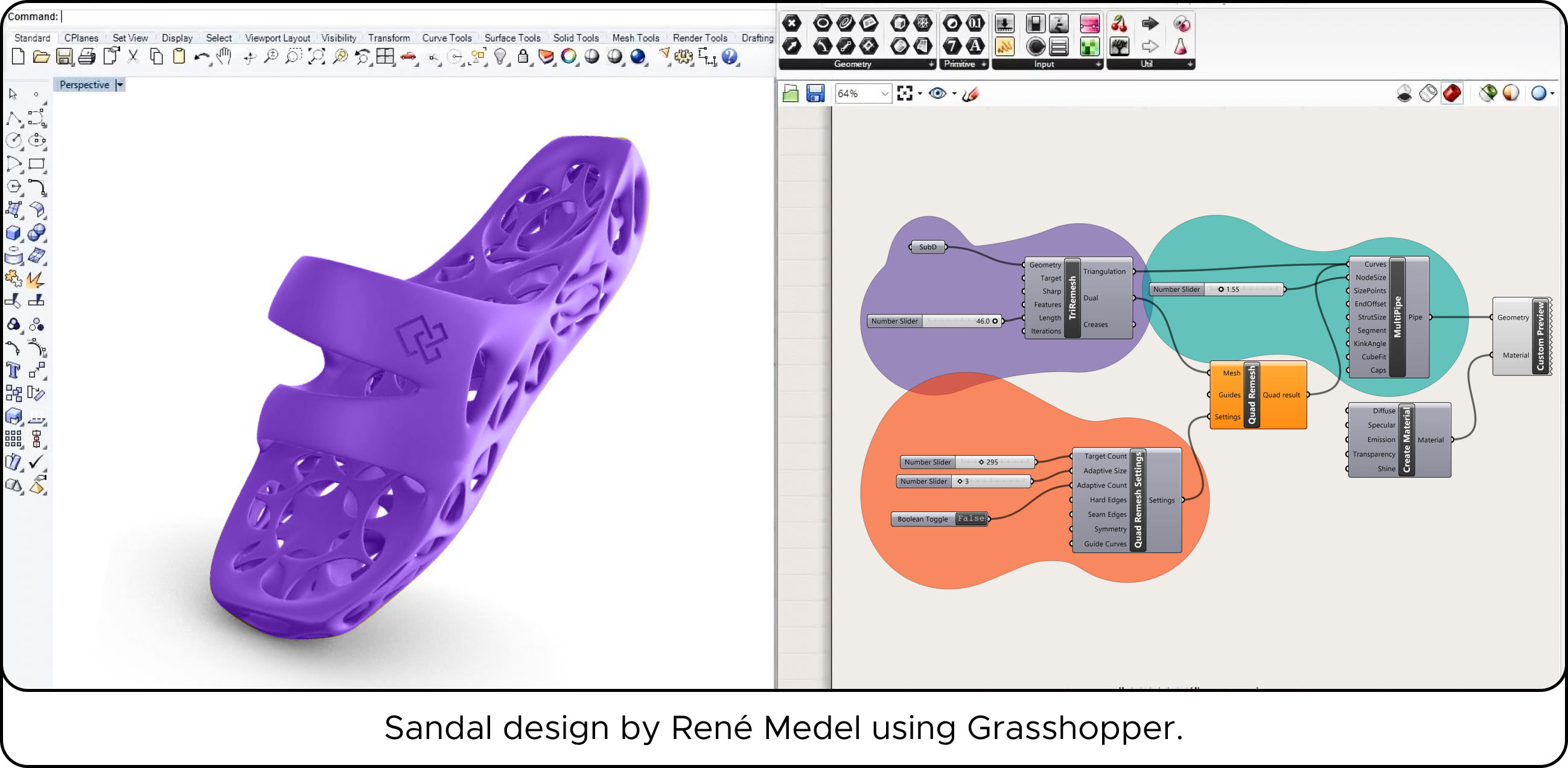

I know it since the "Explicit History" days when David Rutten was still studying architecture, and he came up with these unusual visual algorithms, like worms, and shared them with the active Rhino community. At that moment, I couldn't see the enormous potential of this tool and how it would become the Grasshopper we know now.

8. Why is Grasshopper so important for multiple industries worldwide?

Grasshopper has become a great generative design tool because of the excellent McNeel development, always open to the community and third parties developing their plugins for growing this algorithmic modeler.

Several industries get the benefits because it is about parametric design, not only for engineering but for real creative ways of form-finding, iteration, and customization.

9. What’s your vision for how Grasshopper can be used in the footwear industry?

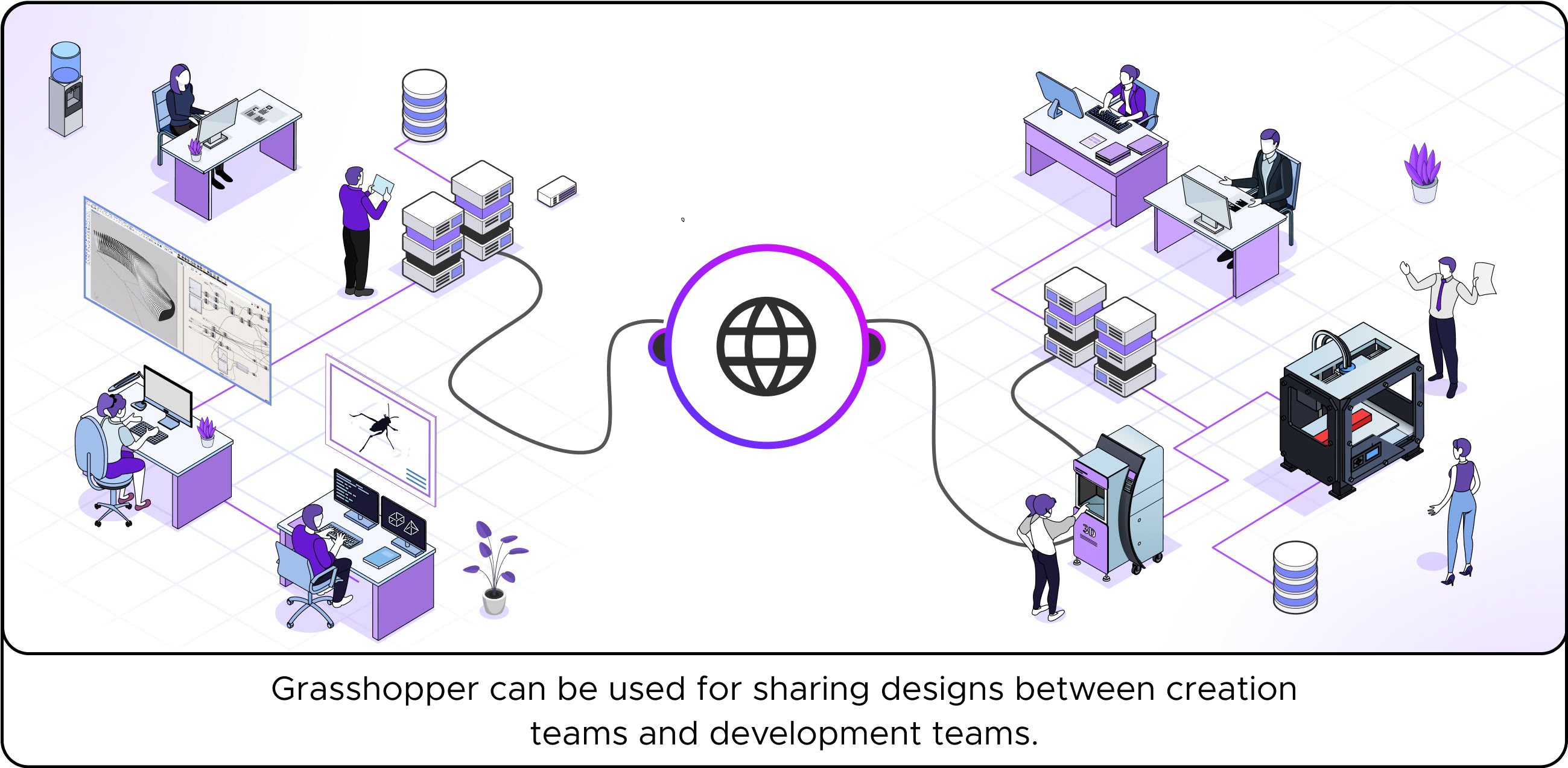

I think Grasshopper could be used in several stages. Obviously, the most direct is for sharing designs inside creation teams and with development teams. Internally is easier to share some ideas and concepts with other team members not using Rhino actively. Nonetheless, we can share some definitions with customers or partners for evaluation and feedback.

10. What are the status quo and the main challenges for Grasshopper (or parametric design) to be widely adopted in the footwear industry?

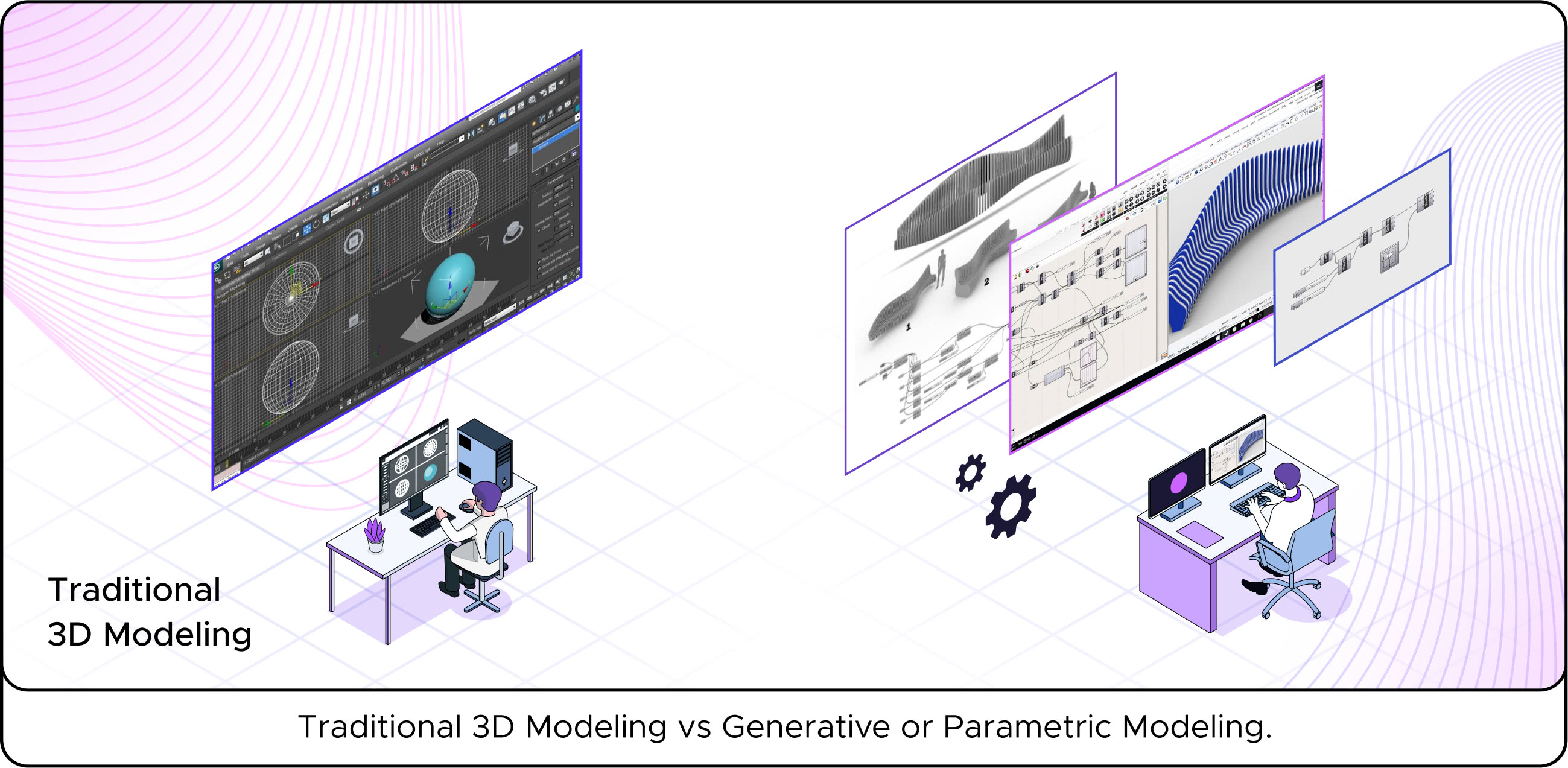

Actually, 3D modeling is widely used in the footwear industry, but generative design is still not mature enough. We, designers, need to move forward to keep on creating generative yet.

11. Can you share any examples of how your use of computational design has led to an increase in efficiency or cost savings for your clients?

Since I work in Innovation, we are dealing with projects for 3-5 years ahead. So I can't disclose actual projects. However, I could say that we are optimizing not only products or what we do but also production/productivity or how we do it.

12. How can additive manufacturing potentially improve processes in the footwear industry?

Additive Manufacturing is part of Industry 4.0, and now we are integrating it into production, not only for rapid prototyping as usual.

AM supports the traditional manufacturing processes giving more freedom for complex geometry fabrication, not only for final products but mainly for optimizing actual existing machinery. Automation and robotics are present in the factories, and AM helps to supply effectively spare parts, jigs, fixtures, and molds.

13. What are lattice structures, and why are they so important and revolutionary?

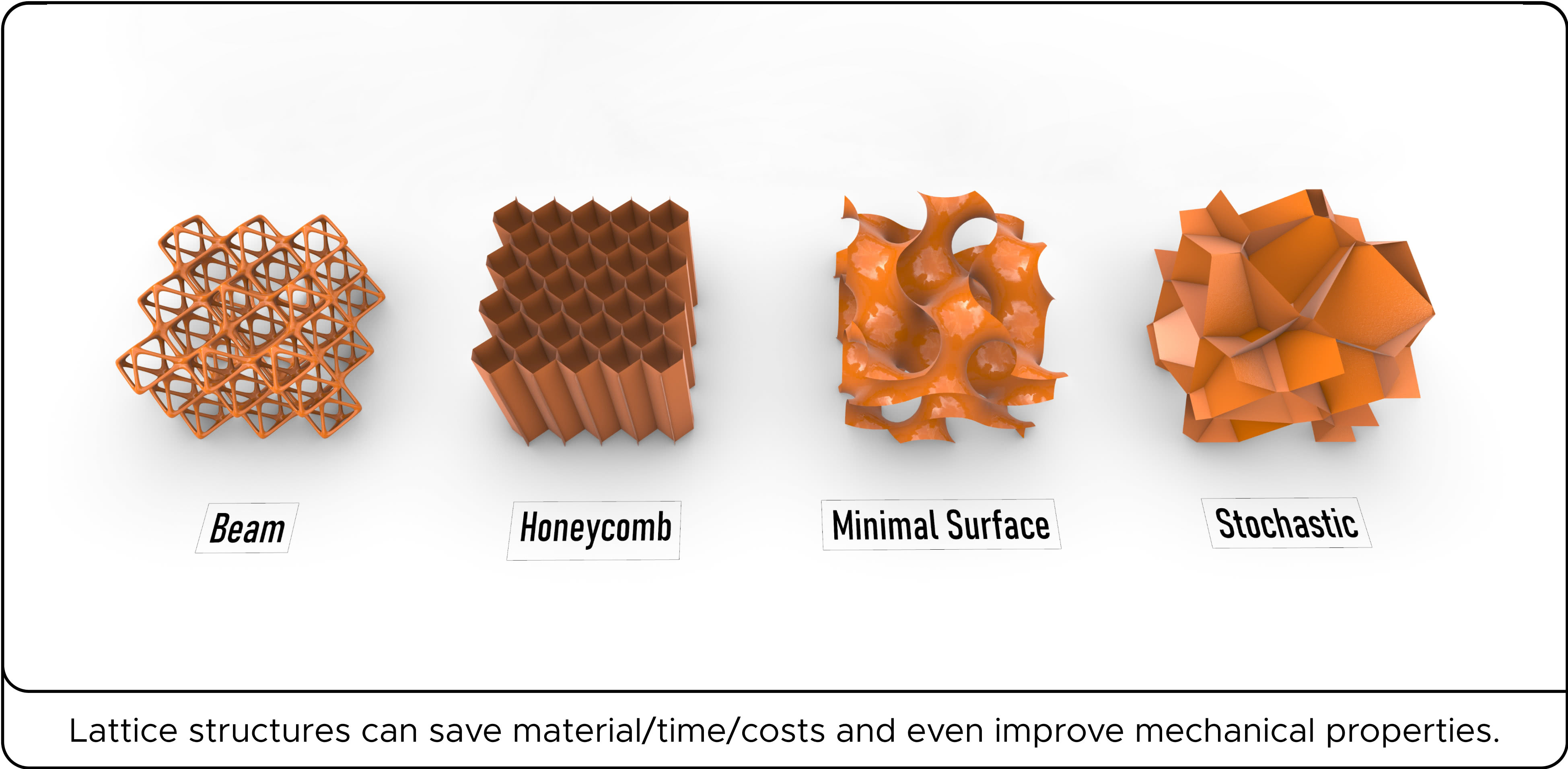

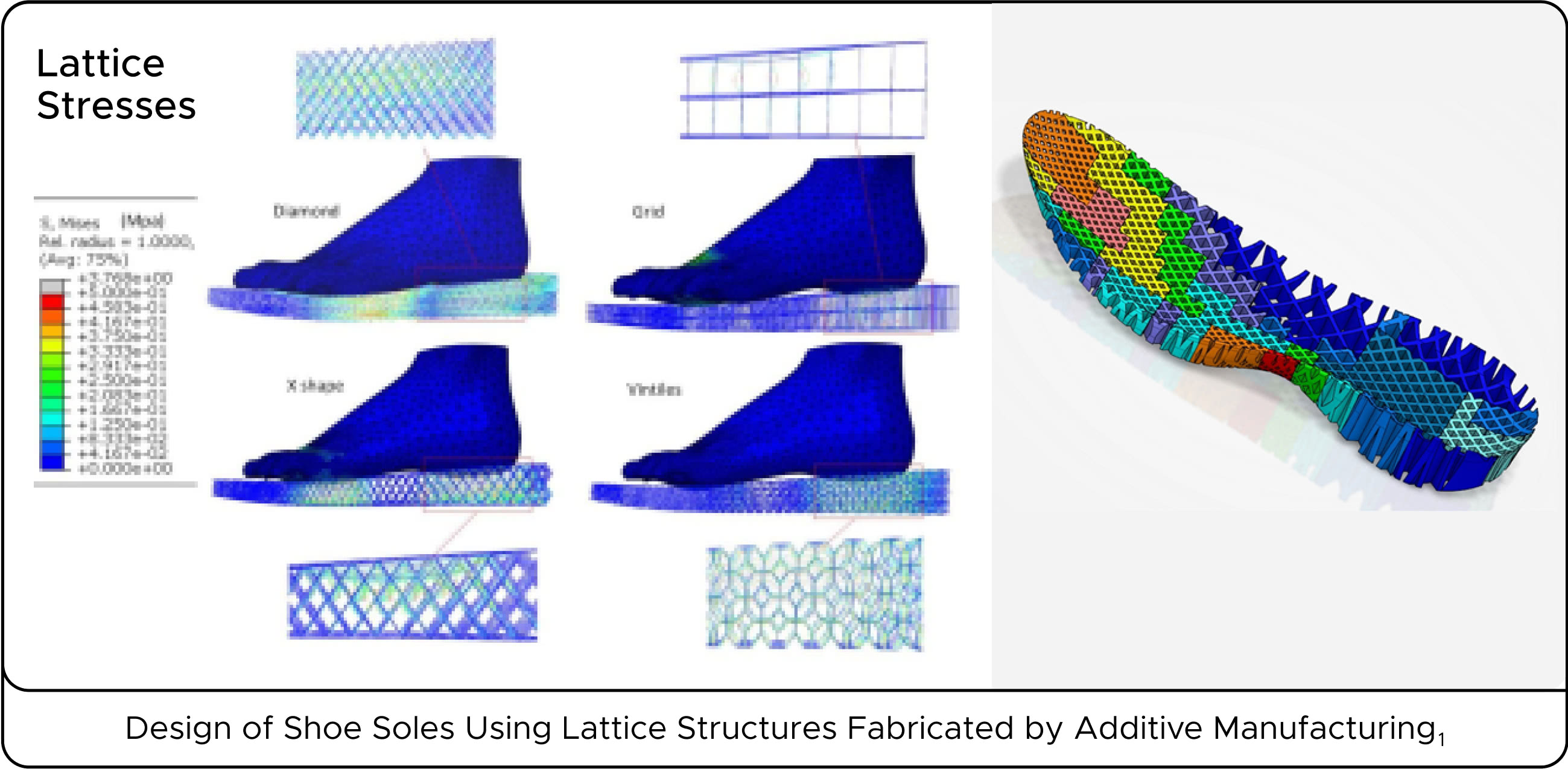

Lattices are structures that conform to cellular patterns. These could be periodic or not. In this last case, a stochastic lattice looks a bit chaotic because we can not find a cell repeating. The periodic lattices are mainly these 3 types:

a) Honeycombs or prismatic b) TPMS or Minimal Surfaces

c) Beam

Lattices are important because they could replace solid parts, saving material/time/costs but keeping or even improving the mechanical properties of the parts. These could not be fabricated with traditional processes, so that is why AM is the key.

14. What’s the main challenge behind calculating lattice structures?

The challenge is to keep the mechanical properties when the lattices become conformal. In other words, when it fits inside the given volume.

A second challenge is to define the purpose of the lattice. It could be just weight saving, thermal dissipation, foaming/cushioning, energy absorption/rebound, osseointegration (medical), or simply aesthetic design.

15. How do you stay current with advancements in technology and design trends in the footwear industry?

By being aware of the new developments from software providers, material suppliers, manufacturers, startups, academic research, visiting trade fairs, and partners.

16. In your opinion, what is the most exciting or innovative use of computational design in the footwear industry that you have seen or been a part of?

I think the most interesting so far is to see the software improvement and 3rd parties development. Some algorithms created more than 40 years ago, like Polygon Subdivision (SubD), now integrated into Rhino to work together with NURBS and Meshes, are amazing.

When you can show and share this using Augmented Reality, makes your work much easier to be seen and understood.

17. What’s the future of the footwear industry?

17. What’s the future of the footwear industry?

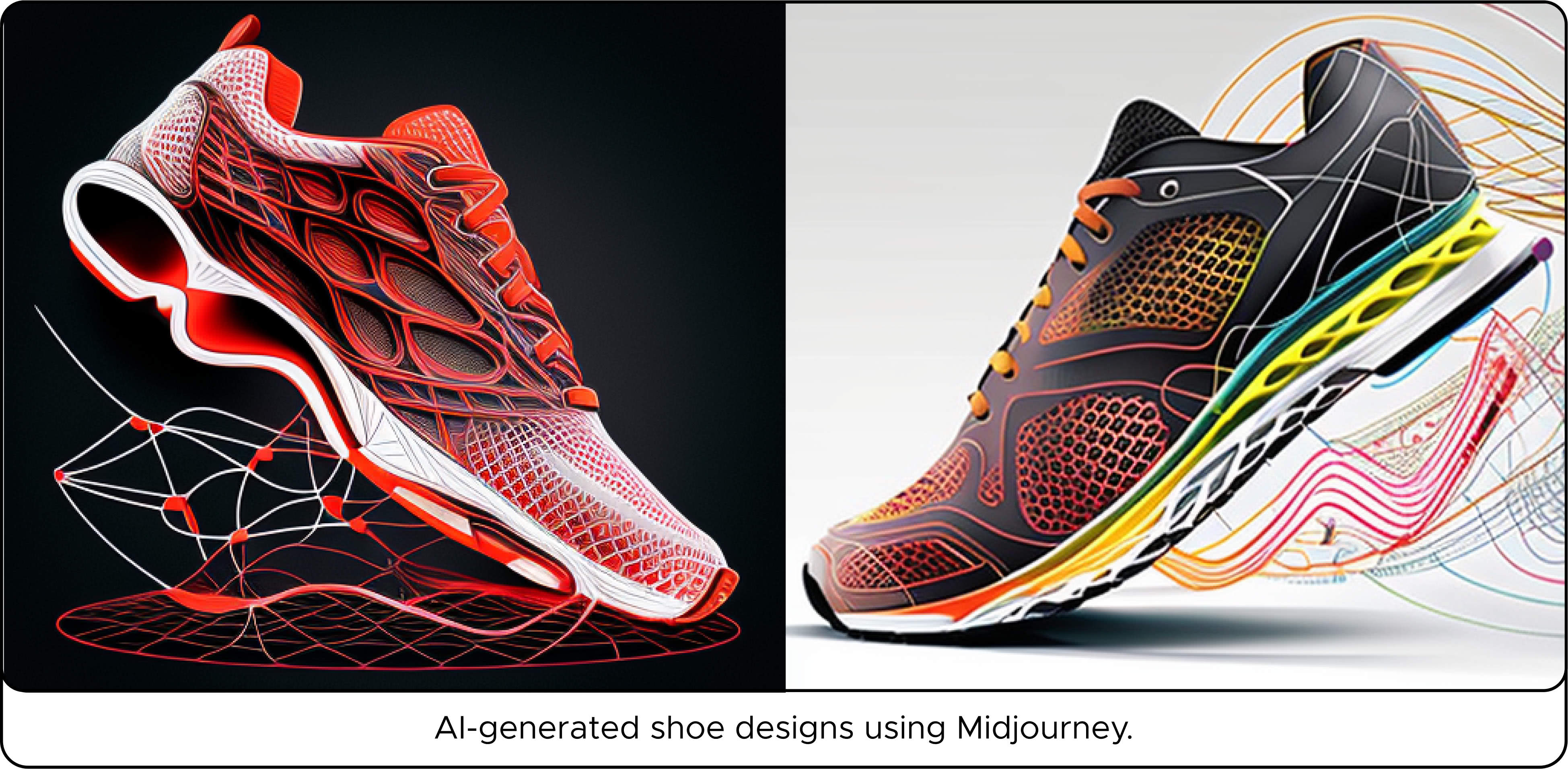

I believe that, like in many other industries, footwear will be affected by Artificial Intelligence (AI). That’s why I asked ChatGPT about this future, and I can only agree because it matches with the previously mentioned :

"The future of footwear is likely to involve a combination of new technologies, materials, and design approaches. Some potential developments in the field include:

- 3D printing: This technology could be used to create customized, lightweight, and durable footwear that can be produced on-demand.

- Smart features: Footwear with built-in sensors and connectivity could track activity, monitor health, and adjust to the wearer's needs.

- Sustainable materials: As consumers become more conscious of the environmental impact of their purchases, footwear made from recycled, biodegradable, or plant-based materials is likely to become more common.

- Augmented reality: Footwear with augmented reality features could display information or enhance the wearer's physical experience.

- Performance-enhancing: Advancements in materials and manufacturing techniques could lead to footwear that enhances the wearer's performance, such as by providing extra support, cushioning, or propulsion.

It's also worth noting that there is a growing interest in minimalistic and natural movement footwear that mimics the feel and movement of being barefoot, as well as the use of natural and renewable materials.

Overall, the future of footwear is likely to be defined by a focus on customization, sustainability, and technology.”

- We couldn't agree more as well! Thank you, René, for your time today!

You are welcome. Thank you for the opportunity to share my work at framas.

That's it for this new edition of Designers Corner. Don't forget to visit framas blog and follow them on Instagram !

Would you like to get featured in this space? Please email us at contact@shapediver.com and tell us about your project or brand! We'd love to start a conversation.

/f/92524/1200x630/66a3c4178a/cover-photo-inside.webp)