Fusing aesthetic finesse and functional precision often leads to success in design and manufacturing. Modern Metal is an American company that specializes in creating bespoke metal panels and vent covers for architectural projects. The company has an interesting history, starting from textile roots and growing into a fully-fledged metalworking venture under the leadership of Annie Kantor.

Recently, Modern Metal has been committed to innovation and, most importantly, automation, which is evident in its use of digital tools like CraftOS and ShapeDiver. CraftOS is a turn-key solution that combines the creative freedom of Grasshopper and ShapeDiver with the operational efficiency of custom order management. (We'll have an interview with their team soon, so stay tuned!) These tools allow the company to refine its design process and customer interaction, resulting in high-quality products that meet the needs of their clients.

In this interview, you will discover the journey of Modern Metal and their decision to integrate CraftOS into their platform. As Annie discusses their operational challenges, she highlights how CraftOS has become a cornerstone in simplifying the process from design to order fulfillment. This conversation will provide insight into automated design customization, real-time quoting, and the future of customer-centric digital interactions for Modern Metal. Let’s dive in!

1. Can you tell us about the journey of Modern Metal from its inception to where it is now? What drove you to transition from a background in textiles to specializing in metal panels?

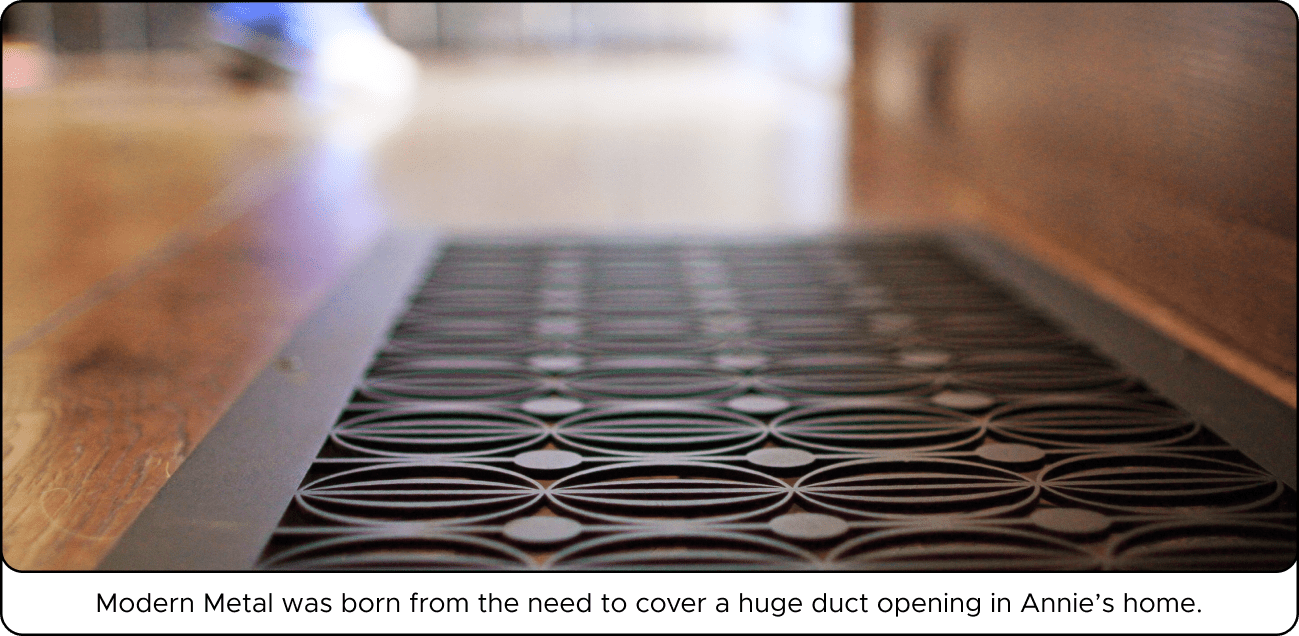

It has been an unexpected adventure from its inception! This all started because I was in the midst of remodeling my Oakland home, and I was attentive to every detail. We had a huge duct opening in the entryway to our home. I scoured antique markets for a beautiful brass floor grille that would suit the aesthetic of our home. I couldn’t find anything the right size. I remembered a jacquard woven textile I had designed years ago, ironically inspired by a metal elevator shaft extracted from the Chicago Stock Exchange, a Louis Sullivan building. I thought it would be interesting to translate my woven into metal. Our architect saw this and said, “Hey, this is really cool you could sell these”. And just like that, a business was born.

Today, I use a Textile Design program, Pointcarre, to design all of my patterns in metal. It’s comfortable for me to think and work as a textile designer, to think in repeating patterns. This enables me to push the limits of what can be done in metal, creating more textile-like designs with more movement and fluidity.

Thus, the core of what I started with remains the same as I’m designing repeating patterns, but instead of using layers of yarn for dimension and structure, I’m using metal. The business has evolved significantly from that beginning point.

Now, I’m running a company, wearing lots of hats, and very little of my time is spent on pure design work. We’re officially a Women-owned Small Business, and I work closely with my core team of women, production manager, and operations manager to keep the flow of our business running smoothly. It’s a lot of work!

2. Who are your primary clients, and in what ways do Modern Metal’s products cater to their specific needs?

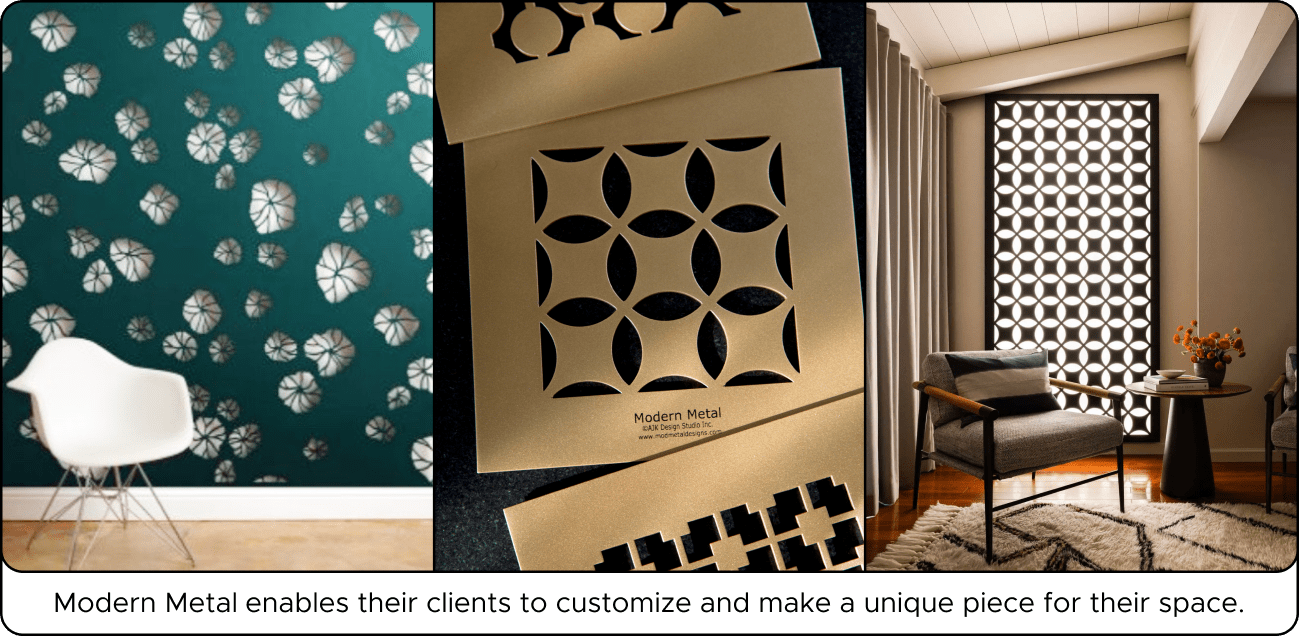

Primary clients are architects and interior designers in the residential and commercial spaces. We do sell directly to homeowners, but our primary focus is business-to-business. Modern Metal enables our clients to customize and make a unique piece for their space.

Most often, almost always, a designer needs a very specific size and wants to develop a custom pattern with us. My goal is to make the custom process easy, fun, and efficient so that they can incorporate Modern Metal into their projects. The result is a long-lasting bespoke design element personal to their customer/project.

3. Your products, especially the large format custom frame panels and vent covers, uniquely blend aesthetic appeal and functional value. How do you manage to balance these aspects in every project you undertake?

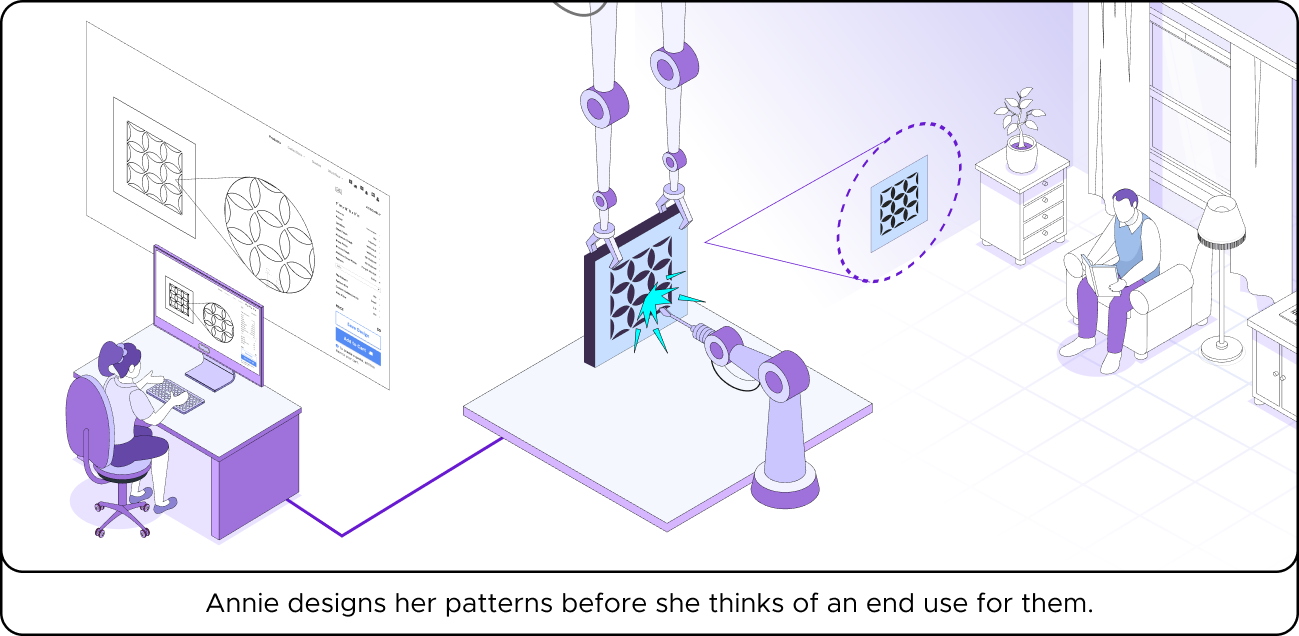

I’m all about form and function; one doesn’t happen without the other. Whenever I develop a pattern, for instance, I think of the end use. Actually, I develop the pattern BEFORE I think of end use so that I’m less inhibited. Then, I start the questions and make appropriate edits. How much opening space does it have for airflow? How sturdy will this design be if cut in a large panel? Depending on the application, we consider many factors, such as the scale of pattern, thickness of material, type of metal, and finish for various climates. Our products are designed to be forever products in timeless designs.

4. When it comes to customizing vent covers and panels for your clients, what are the most common customizations requested, and how do you accommodate them in your design process?

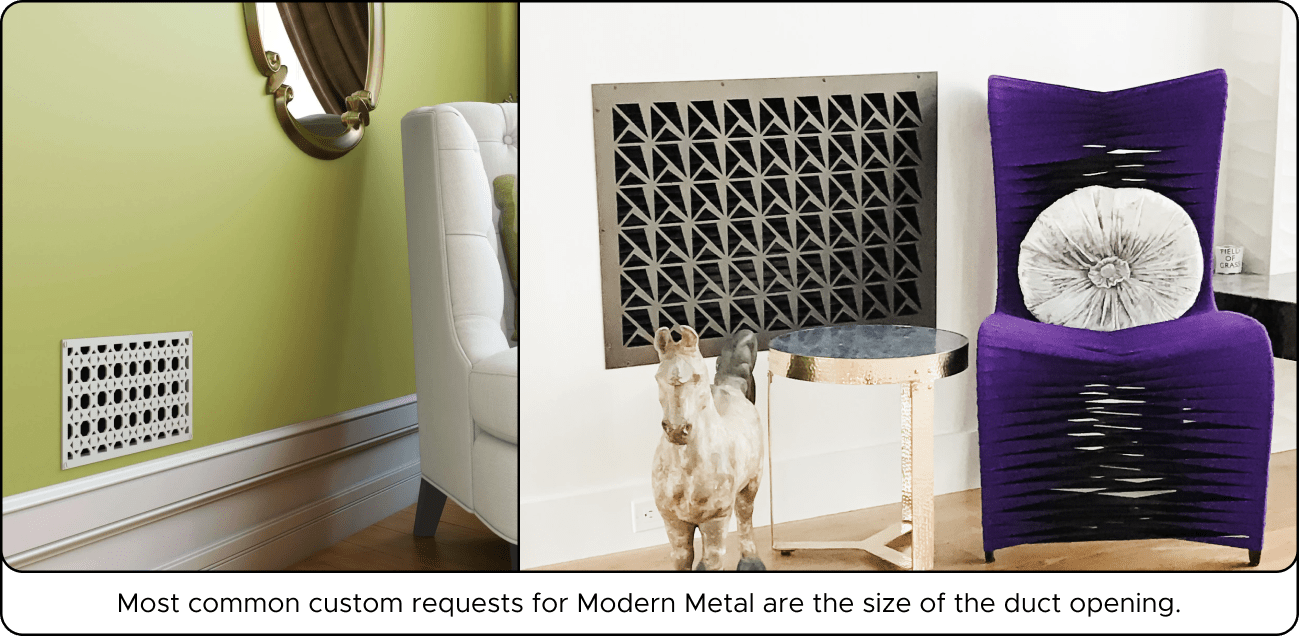

The most common custom requests are the size of the duct opening. Sometimes, clients also need a certain outer dimension to cover up something unsightly on the wall. It can be a technical challenge to adjust these parameters as the pattern area is dictated by flange welding, and screw sizes may dictate the outer edge, etc. In cases like this, I have to have the technical dictate my design direction, and I work within those confines. I don’t mind this because I welcome a design challenge. When I worked as a Textile Designer at Maharam, we designed commercial fabrics that had to meet standards, such as double rubs, etc. I love the challenge of creating something beautiful that meets the guidelines. Again, form and function!

5. Over the years, what were some significant challenges Modern Metal faced, especially in terms of design customization and order fulfillment?

Challenges–yes, there have been many. I still feel like I learn something with every single job. Right now, we’re designing a gate in collaboration with Creative Gates. My design is intended to span across hopping from one gate side to the next, and I have to consider the gate frame and hardware. That’s new for me and a challenge.

We’ve learned everything the hard way! We don’t ship until payment is received. We have strict proof of packing in case an item gets damaged in shipping. We insure everything. We double-check all quotes and drawings through a rigorous internal check system to ensure we don’t miss details. We bubble close-ups of our drawings so customers understand the pattern's scale. We make sure to write that our designs are strictly copyrighted and may not be reproduced or fabricated without our written consent. We give conservative lead times to have some extra time built in should something need more time.

Mostly, we have implemented a very formal process for sign-off of drawings, estimates, and shipping to ensure we communicate clearly with our customers. Metal is not forgiving, so it needs to be accurate the first time!

6. What motivated you to integrate CraftOS into your operations, and how has this decision impacted your handling of custom orders?

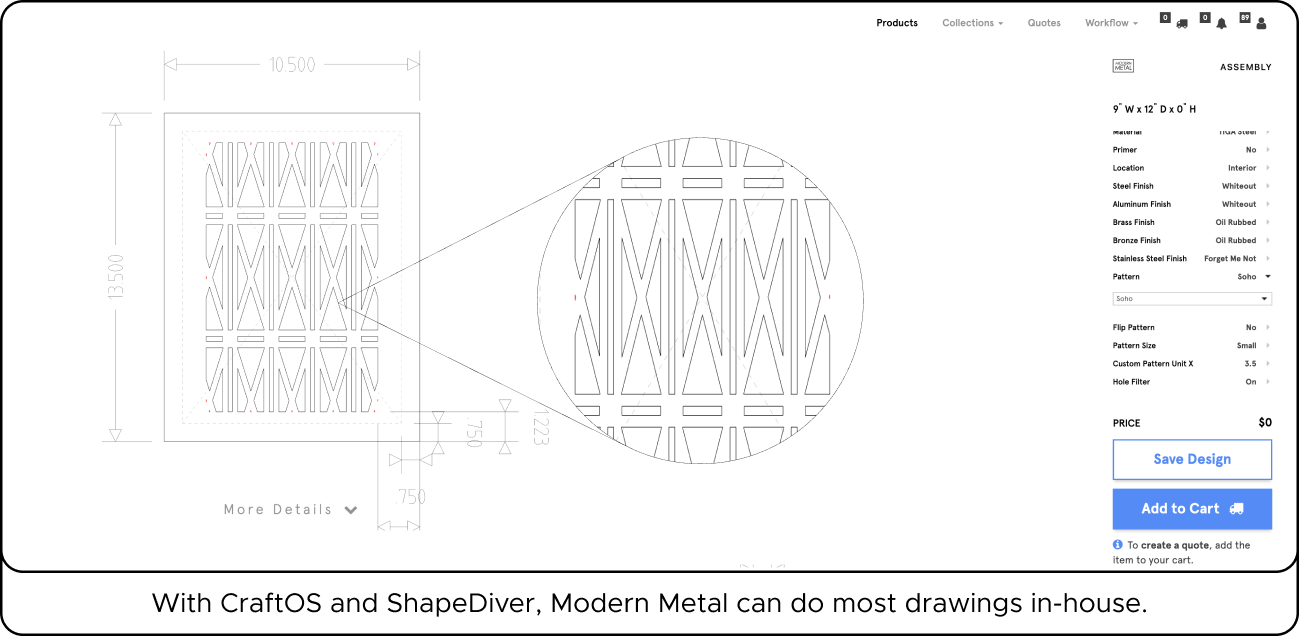

I had been outsourcing all of our technical drawings to CAD engineers. I still do that, but now, with CraftOS, we can do most drawings in-house and don’t need to wait days to receive them. We can revise on the spot! The process is integral to quoting and providing our customers with accurate technical drawings.

7. Before creating this online automation tool, were there alternative solutions you considered for handling these automation tasks? What sets this new tool apart in terms of cost and value?

Before, we only outsourced to CAD engineers. What sets this tool apart for us is the ability to customize to our needs. We spent hours with their team so that they could understand the nuances of our product and build it into their model.

8. How have the capabilities of this tool in handling multiple quantities, material choices, and different finishes streamlined the product customization process at Modern Metal?

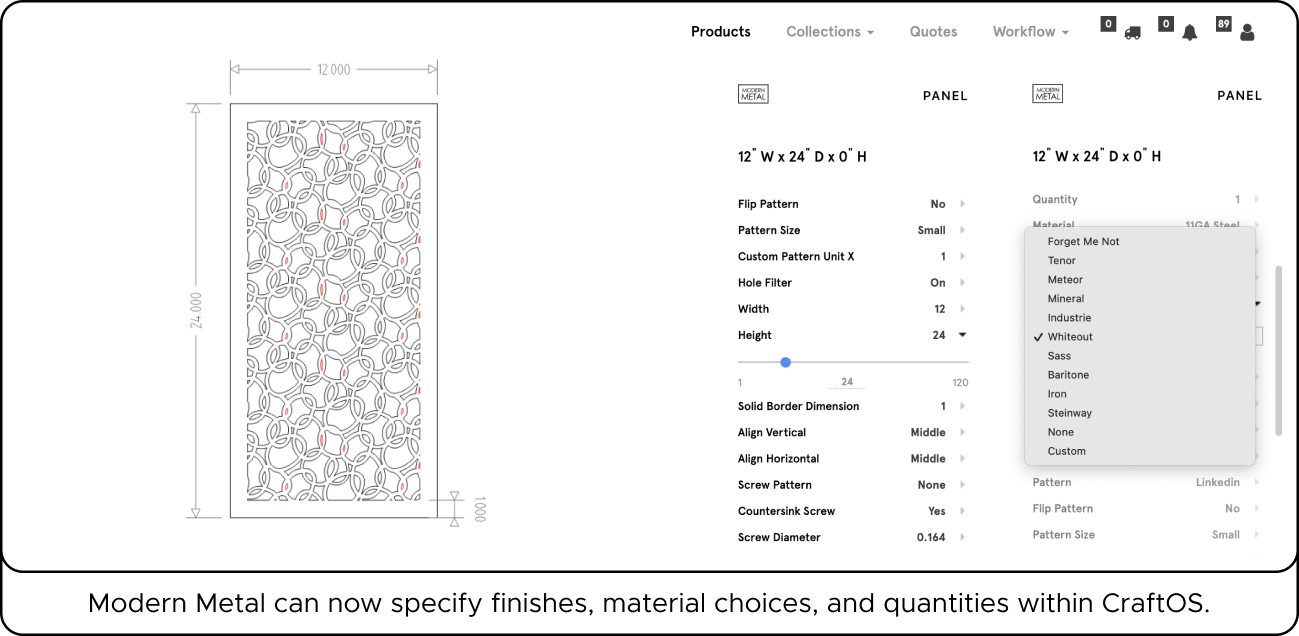

This hasn’t really changed anything for us in this regard, but we are able to specify finishes, material choices, and quantity in the program, which is important.

9. How has it simplified creating custom product configurations and affected lead times and productivity?

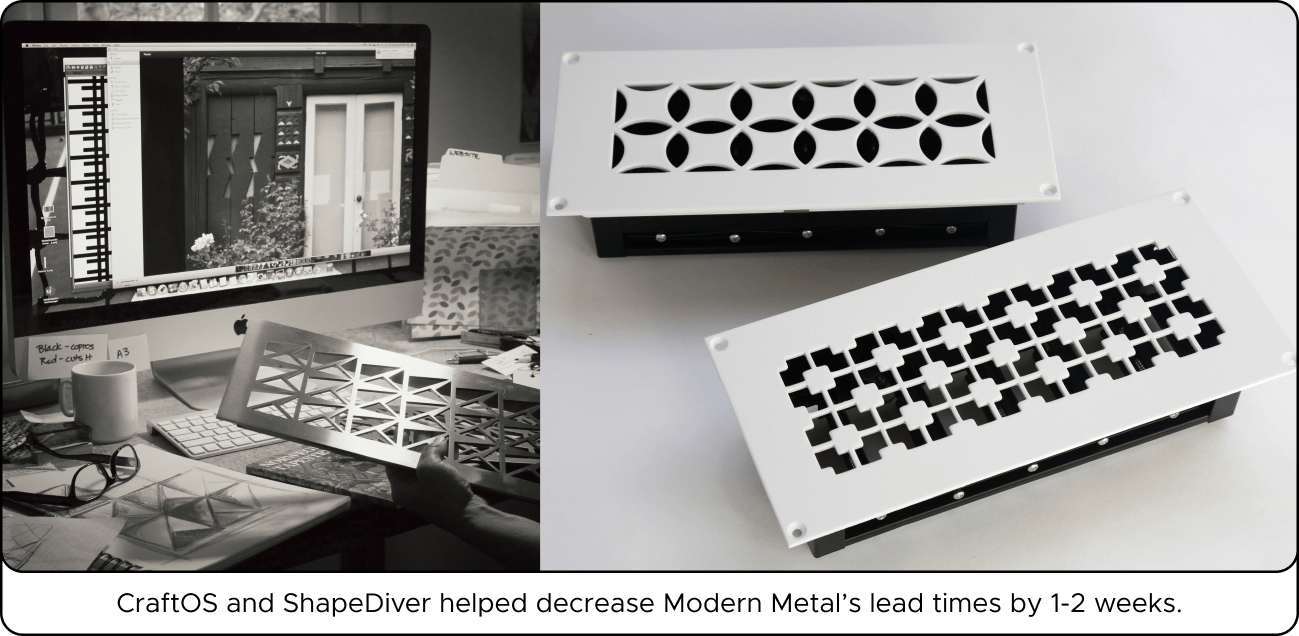

We can now draw our products in custom sizes very quickly, which enables us to receive quotes from our fabricators faster and get our estimates to the customer faster. I’d say this has decreased our lead times by 1-2 weeks.

10. How can automatically generating and managing quotes and processing orders through this tool enhance your customer interactions and sales process?

Sometimes, when I feel a customer needs a visual, I just create a drawing for them in CraftOS to look at. This was not possible for me previously and is certainly a great selling tool.

11. How does the tool alert the designer about potential fabrication issues? Can you share how this feature has helped minimize errors or rework in the design phase?

There are what CraftOS calls “rules” in our customized program, which make designing our products a dream and easily accessible for anyone on my team to develop. Here are two examples of how these rules minimize errors in the design phase:

- Minimum opening size on a pattern. CraftOS has programmed in a rule that no opening can be smaller than the thickness of the metal we’re cutting. This is a fabrication rule and essential for us to follow. So now, anytime we enter an opening size that won’t be possible to cut, it shows up in red as an alert to us. It’s great!

- Scale of pattern: We have established three set standard scales of our patterns for all of our 21 Signature Designs. This rule enables us to be consistent when designing so that our scale remains the same across a job. Also, it enables my team members to know my suggested guidelines for the pattern scale of each design.

12. What kind of feedback have you received from your clients or fabricators regarding the automated schematics and cut files generated by this tool?

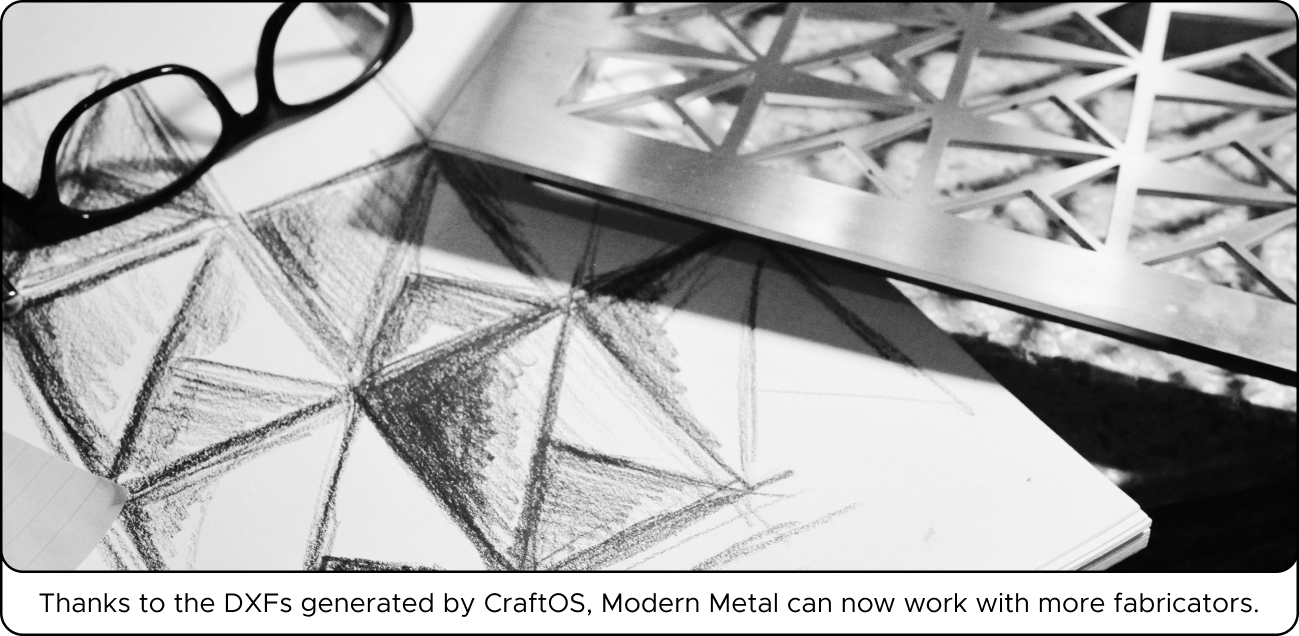

Our fabricators appreciate DXF files, and we can now work with fabricators who may not have been able to quote for us previously without the DXF file. This tool has opened new doors.

13. How do you envision the evolution of the configurator tool, especially in terms of customer-facing interactions and direct ordering?

Right now, we’re not using it to its full capacity. I’d like to get to the point where pricing is instantly generated. At some point, we’d like our customers to be able to customize our existing Signature design on our website, get a price, click, and order!

14. As Modern Metal continues to evolve, are there new product lines or design innovations you are exploring to enhance your product portfolio?

Yes, we are about to formally introduce a new product, a very engineered and customized piece that opens and shuts to accommodate changing an air filter. Also, we plan to introduce a semi-custom value-engineered option for cabinetry inserts in our most popular pattern, Square Squared. Lastly, I have a new collection of designs on the horizon!

15. Based on your experience, what recommendations would you give similar businesses looking to automate their design and order fulfillment processes?

I’d say it’s a necessary step to streamline production and stay at the forefront of technical innovation. Just like buying the most recent software, we must keep up with what technology has to offer!

- Thank you very much for your time today, Annie!

Thank you as well for this opportunity.

That's it for this new edition of Getting to know... Don't forget to visit Modern Metal’s website and Instagram page .

Would you like to get featured in this space? Please email us at contact@shapediver.com and tell us about your project or brand! We'd love to start a conversation.

/f/92524/1200x630/d5bab4e327/cover.webp)