MERZ MÖBEL, a German furniture company, recently released a brand new website where they feature several highly customizable pieces of furniture designed by Ulrich Merz and his team. We thought this was a great reason for us to invite him for a discussion around his brand new concept, how it got started, how he manufactures these pieces and how Grasshopper and ShapeDiver are helping him stand his ground in an industry dominated by a few big players. Hope you enjoy this interview!

1. Welcome, Ulrich. Thank you for joining us today! Tell us a bit about your background.

Hello! Thank you for having me. My name is Ulrich Merz. By profession I am a product designer. I used to live in Berlin for many years and relocated to my home town Regensburg with my family recently. I am married to a ENT (ear, nose, throat) physician and we have three kids together.

I equally enjoy designing and engineering. Apart from my new venture, I support industrial clients at new product developments. What I love about my job: design embraces a variety of fields, such as materials, process and technology, manufacturing capabilities, economics, strategic thinking and product life cycle. That makes it a key success factor for business.

2. How did MERZ MÖBEL get started? What triggered this idea?

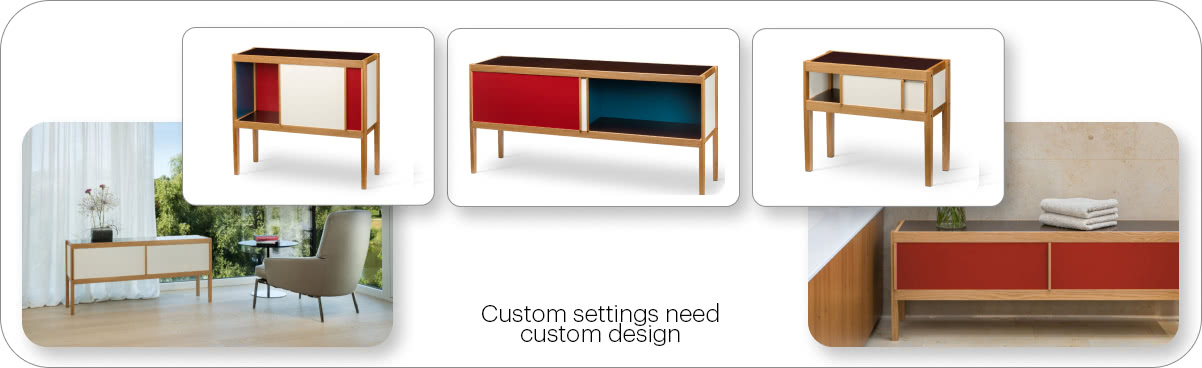

The furniture we bring to market is a classic sideboard with a certain mid-century appeal. We designed it while running our studio in Berlin. The first prototype got sold instantly. Shortly thereafter, a client asked for a series of sideboards, but requested different dimensions, as well as colors. Many years later, people kept appreciating the design of our sideboards and time proved it’s functional and visual longevity.

During the pandemic, we felt the urge to start something new and began developing the MERZ MÖBEL business case for the production and distribution of our customized design sideboards M4313.

3. What type of changes are you trying to bring into the Furniture Industry?

Today, many interior products come with options for individualization, such as the number and height of compartments or a color palette to choose from. In contrast to this traditional approach inside a system, the freedom of customization we offer to our customers results in a truly unique piece of furniture, because all dimensions can be defined incrementally and independently. MERZ MÖBEL lets customers define their own collectors item according to their needs!

4. What types of production methods do you use and why?

The M4313 sideboards are produced in highly specialized environment. Every production step is designed for efficiency, process control and safety. We use conventional woodworking machines, which are partly complemented by special devices and 3D printed adjustment adaptors to guarantee consistent precision and quality and to reduce set up times. We do without automated manufacturing: Solid wood deserves manual work, doesn’t it?

5. Absolutely! How is Grasshopper involved in your processes and why? What are the benefits this parametric approach?

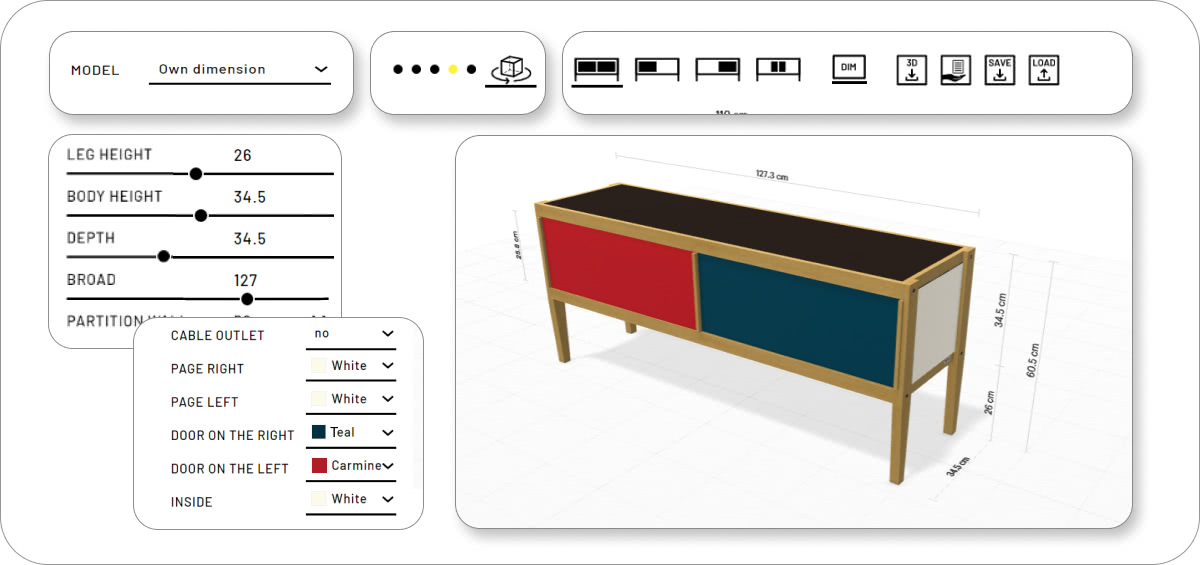

The Grasshopper asset is the invisible hand in the process and does the magic before production. The algorithm computes a visual representation of the model, so that users can see what they get while they're configuring their piece. But there is a lot more going on under the surface.

For example, pricing is calculated automatically, taking into account material cost, production and handling cost as well as packaging and shipping expenses. We use the plugin Squid to export the production parameters along with a unique order number and then print it out on adhesive labels. The numbers are applied to every component during production so every part is traceable.

Parametric design often displays generative patterns or complex structures but it is applicable to any conceptual work. The possibilities with Grasshopper are literally borderless, this is what makes it so powerful!

6. How is ShapeDiver helping you build your business?

ShapeDiver is the linking part between the Grasshopper definition and the web API. Also, ShapeDiver hosts and computes the Grasshopper file.

Thanks to a comprehensive documentation, our programer easily understood the concept and I believe he had a good time while implementing the configurator. The customer service includes a Support Forum where I rarely waited more than a day to get useful answers to my questions!

7. What aspects were the most important when designing your UI and UX?

Complex interactions can be overwhelming for users. That’s why we designed our user interface to be playful and easy to comprehend.

With it, users can easily choose from a drop down menu of six predefined models and order directly but they are also encouraged to alternate dimensions and play around with color combinations.

In addition to this, we integrated a camera behavior that is responsive to user inputs. For instance, if the side panel color is changed, the model will automatically switch to that side. Also, changes in dimensions always lead to a slightly new and fluent camera adjustment. It’s these little feedback details, that make a good user experience!

8. What is the design detail you like the most about your products?

There are plenty of things we like (we're biased!). We like the overall concept of the solid oak frame with thin paneling, because this solution is robust and reliable without being heavy-weighted itself.

Also, we really love the characteristic corner joints of the M4313 sideboard: they are somewhat brutal and at the same time delicate, precise and flush. But the detail we like the most are the fine grooves for the sliding doors, because they are a nice detail to look at and offer a smooth functionality.

9. What's the future for eCommerce in the Furniture Industry?

In Germany, the furniture market is still dominated by a few big players with stationary branches, but more and more people are willing to buy furniture online.

The share of eCommerce is already above 20% with a 9% growth and we see new online pure player successfully pushing into the market. There will definitely be a huge shift for the benefit of those, how understand how to leverage eCommerce in terms of a strong business model with a premium customer journey. In addition to this, eCommerce can provide a sustainable opportunity for a new generation of niche players like MERZ MÖBEL.

- Thank you very much for your time Ulrich! This has been a great overview of your company.

Thank you as well for having me here! It was a pleasure to discuss this with you.

That’s it for this new edition of Getting to know... Don’t forget to follow MERZ MÖBEL directly at their LinkedIn and Instagram accounts!

/f/92524/1200x630/6a62fcdbf7/merz-moebel-shapediver.webp)