Meet Indimise , a German company that allows anyone around the world to 3D print their own smartphone case without the need for any technical experience, special CAD design software, or their own 3D printer. Excited? So are we. Let's dive straight into the interview!

1. Welcome, Sebastian. Thank you for joining us today! Tell us a bit about your background.

Hello everyone! Thank you for having me here. I am Sebastian Flügel. I’m 29 years old and live in the small town of Fulda, Germany.

I love to create new things and that’s why I studied Vehicle Systems Engineering at the DHBW Stuttgart.

Beside Indimise, I am working as a project leader at an innovation department of an engineering supplier. The few hours left of my days are filled with lightweight aircraft flying and Boogie Woogie dancing.

2. What is Indimise?

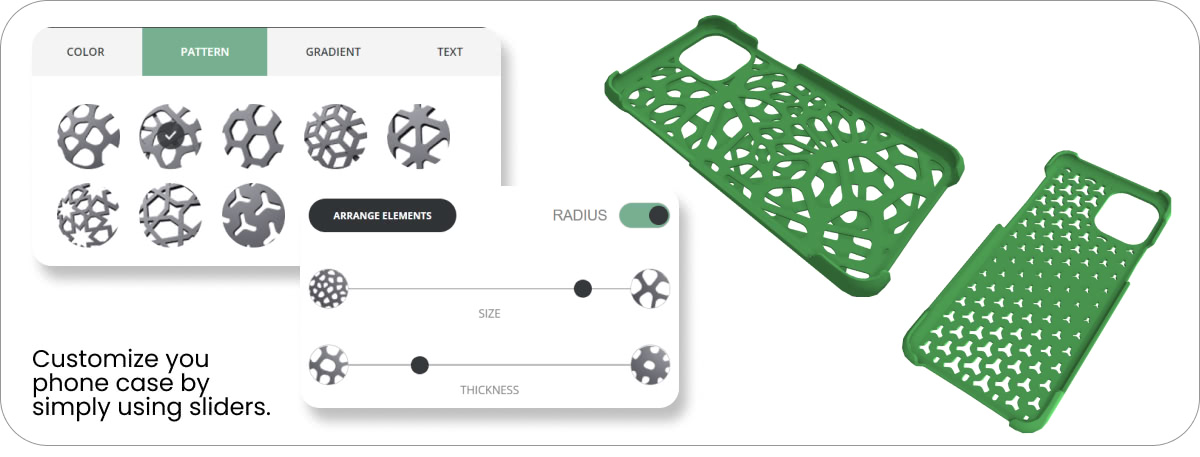

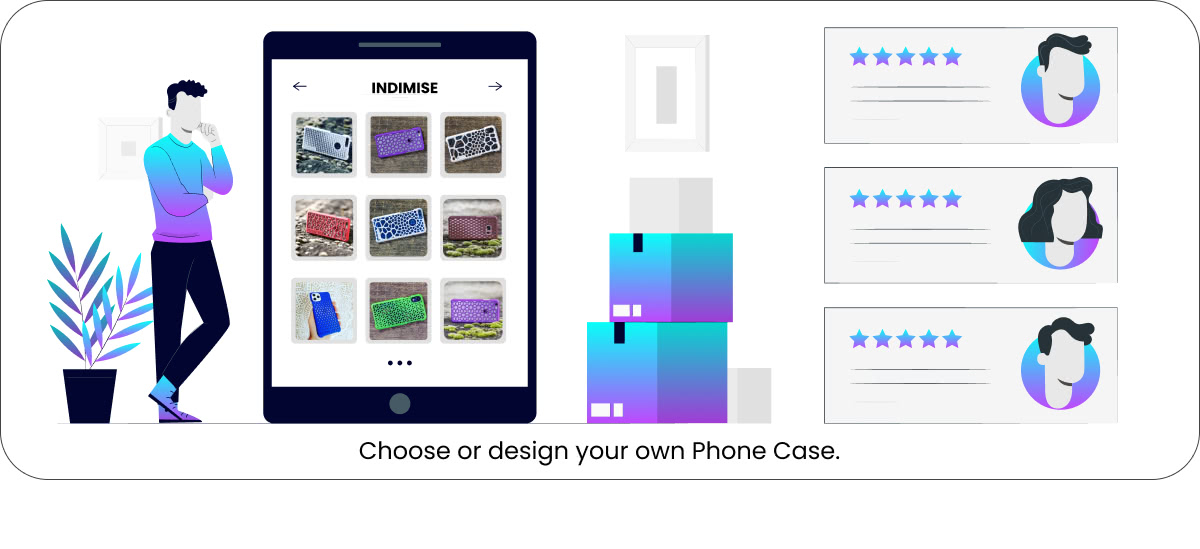

Indimise is a website where everyone becomes the designer of its own 3D printed smartphone case. We provide an online 3D product configurator based on Grasshopper and the Shapediver platform.

With the help of this configurator anyone can customise a 3D pattern, color and engraved text for various smartphone cases. The patterns are inspired by nature as well as modern and historical architecture.

Orders are manufactured on demand by the laser sintering process on industrial SLS machines using the material polyamide 12. Thanks to 3D printing there are no warehouses, no overproduction, less manufacturing waste, and short trading routes. That’s how our smartphone cases are more sustainable.

3. How did it all start? What is the story behind Indimise?

I was on a ferry on the long way home from my motorcycle trip from Morocco to Italy. Inspired by the Islamic patterns that I saw in Morocco, I designed a Christmas present that I wanted to 3D print for my girlfriend who I have not seen for a while.

So I sat there with the CAD software on my PC and someone asked me what I was doing. This person was impressed that I could design and 3D print practically anything. That is when I asked myself “How could everyone get access to the freedom of 3D design and 3D printing?”.

4. Out of all the use cases for 3D printing, why did you choose smartphone cases?

Smartphones became status symbols, but their visual appearance does not differ much. That is why individualization based on 2D photo printing is already a huge topic for smartphone cases. 3D printing and online 3D configurators will add a new dimension to the individualization of smartphone cases.

5. Which one do you consider the best smartphone ever made and why?

It would be easy to call the original iPhone here, because it defined a new era for cell phones. But I never owned one.

I personally consider the iPhone SE first generation as the best smartphone ever made. The simple design is timeless. It had the technology of the iPhone 6, but stayed small despite the trend of big-sized smartphones. Actually, I still use one as my business phone. Small, simple, and well equipped.

6. What were the main obstacles you encountered while creating the whole concept of Indimise?

At first, I thought that I had to develop the whole infrastructure and software to run my CAD files on the cloud on my own. That was too big of an obstacle for me. But then I found several options to host my parametric designs so that my customers could interact directly with the viewer to manipulate the designs.

At the end, I chose ShapeDiver with its integrated features and a big list of supplied Grasshopper plugins, which made it much easier for me to create a better user experience.

7. What is one of your favorite design features of your cases and why?

I personally love most that the case designs are three-dimensional. This attracts attention as it is visually striking. People asked me on the street about my smartphone case almost every day!

8. What are your thoughts on the future of parametric design and 3D printing?

I am convinced that on demand 3D printing is an important step to overcome the age of mass- and overproduction. In future every physical product could be tailor-made to our individual needs as we already get used to it for digital products.

Online 3D product configurators and parametric design are important technologies to make 3D printing attractive and accessible for a wider range of people. The following step would be that people do not have to customise manually on their own, but artificial intelligence creates the individual design for them.

9. What’s next for Indimise? Any new projects you are looking forward to?

We will continuously improve Indimise based on our clients feedback and add new design templates for smartphone cases. We have a lot of inspirations for new patterns that are just waiting to be parameterized and to be explored by our customers. Moreover we have already tested prototypes for other 3D printed customisable products.

10. Where do you see Indimise in 10 years?

In 10 years, customers from all over the world will have access to individualize their own sustainable manufactured unique product on Indimise. Our materials will be 100 % made of renewable materials and every product will be climate neutral. Our AI driven assistant will create outstanding individual designs for our clients.

11. Any advice you could give to anyone creating their own 3D printed products?

Yes! First, you do not need your own 3D printer. Manufacturing platforms offer high-tech 3D printing services like SLS and SLM with much higher quality than consumer 3D printers at a fair price.

Second, you do not even need to know how to use CAD software to make your first 3D designing and 3D printing experiences. You can start at Indimise and customize your own 3D printed smartphone case :)

- Well, thank you very much for your time, Sebastian. This has been an excellent overview!

Thank you as well for having me!

That’s it for this new edition of Getting to know... Don’t forget to follow our friends from Indimise directly at their Facebook and Instagram accounts!

Would you like to get featured in this space? Simply send us an email to contact@shapediver.com and tell us about your project or brand! We’d love to start a conversation.

/f/92524/1200x630/112fdf8ab8/indimise-shapediver-interview.webp)