Introduction:

Andrés Roppa is an industrial designer who has spent more than a decade working at the intersection of eyewear, parametric design, and digital fabrication. This combination has shaped the tools and ideas behind his company: Frame Stock. His path began in Uruguay, where early work with Rhino, Grasshopper, and 3D printing opened the door to remote projects and revealed the untapped potential of customization in eyewear. Over time, this niche focus became his full-time domain, blending the precision of CAD with the craft and aesthetics of frame design.

At the center of our conversation is Frame Maker, his evolving system for transforming 2D outlines into ready-to-prototype 3D frames. Andrés breaks down what it means to automate a process that traditionally relies on a designer’s intuition, explaining both the opportunities and the limits of parametric modeling in a highly artistic industry. He walks through the technical challenges, such as inconsistent curves, hand-drawn variations, and the need to maintain creative flexibility, and how the tool focuses on automating the repetitive mechanics while preserving the designer’s intent.

The interview also explores how ShapeDiver enabled him to transform these parametric workflows into accessible tools for non-technical designers, the role the App Builder plays in building intuitive user experiences, and how bespoke collaborations, such as Vision Now, demonstrate the commercial potential of tailored, on-demand eyewear systems. We close by looking ahead: in-store customization, new materials, evolving 3D printing technologies, and the slowly forming place of AI within the design process. It’s a view into a traditional industry quietly evolving through computation. Let’s dive in!

1. Hi Andrés, Thank you for agreeing to this interview. Could you please share some of your background (education, early professional steps) and hobbies?

Hello, thanks for the opportunity to share. I´m an industrial designer working independently since graduating from design school in Montevideo, Uruguay. I began using Rhino during my studies and continued to develop my 3D modeling skills in the years that followed. This was a big asset in my early product design projects, which were mostly local.

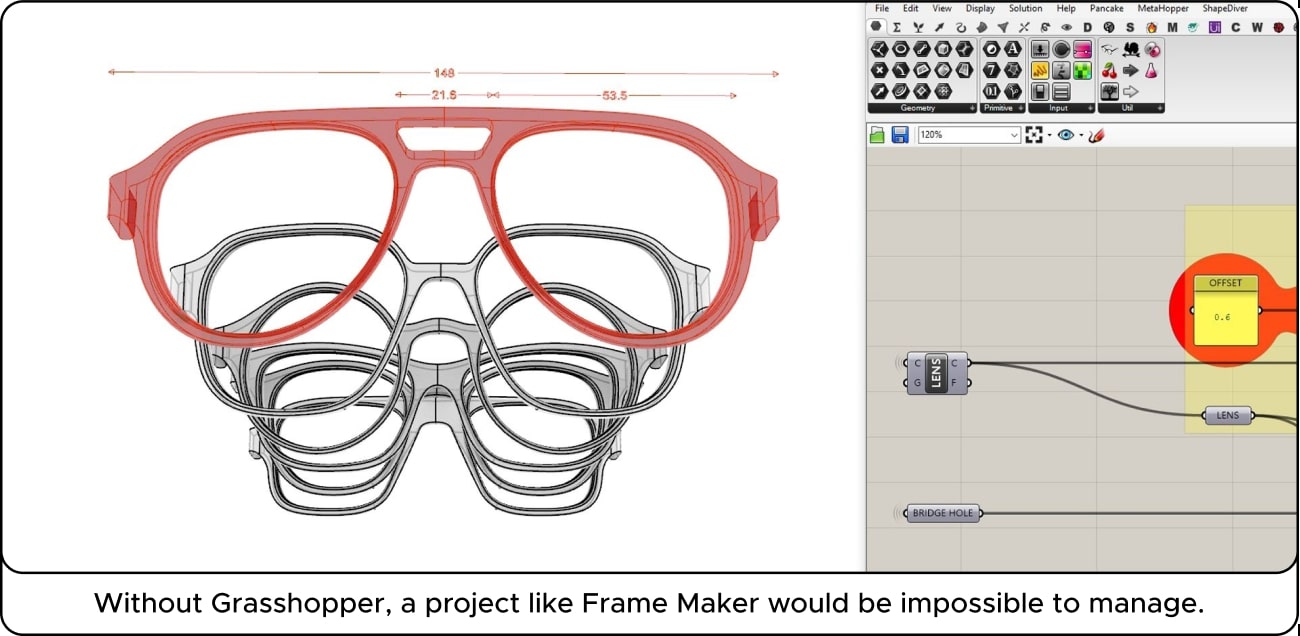

By 2010, I saw 3D printing as the perfect match for my work, because I could now work remotely on bigger, more complex product design projects. Back then, I began to learn more about the industry through a few European eyewear design projects that I was commissioned. I was learning Grasshopper on the side and understood that I could leverage parametric thinking to further develop that synergy between eyewear, parametrics, and additive manufacturing, in search of customization. Fifteen years and many projects later, my attention is fully focused on this niche.

Besides design work, I spend time working on my home and garden, which are part of my other passion: bio-architecture. I live four blocks from the beach and enjoy surfing, swimming, and paddleboarding.

2. What first inspired you to apply parametric design to eyewear? Was there a specific project or frustration that sparked the idea for Frame Maker?

Around 2012, I started experimenting with Grasshopper and designing frames for 3D printing. Back then, frames were already seen as an ideal product for additive manufacturing. I understood that pairing this versatile production method with parametric design would create opportunities for mass customization down the road. Frame Maker evolved as a solution based on these previous experiences, which taught me a great deal about the eyewear industry, which was new to me.

3. Eyewear design blends aesthetics, ergonomics, and engineering. How did your background as an industrial designer shape your approach to automating such a craft-driven process?

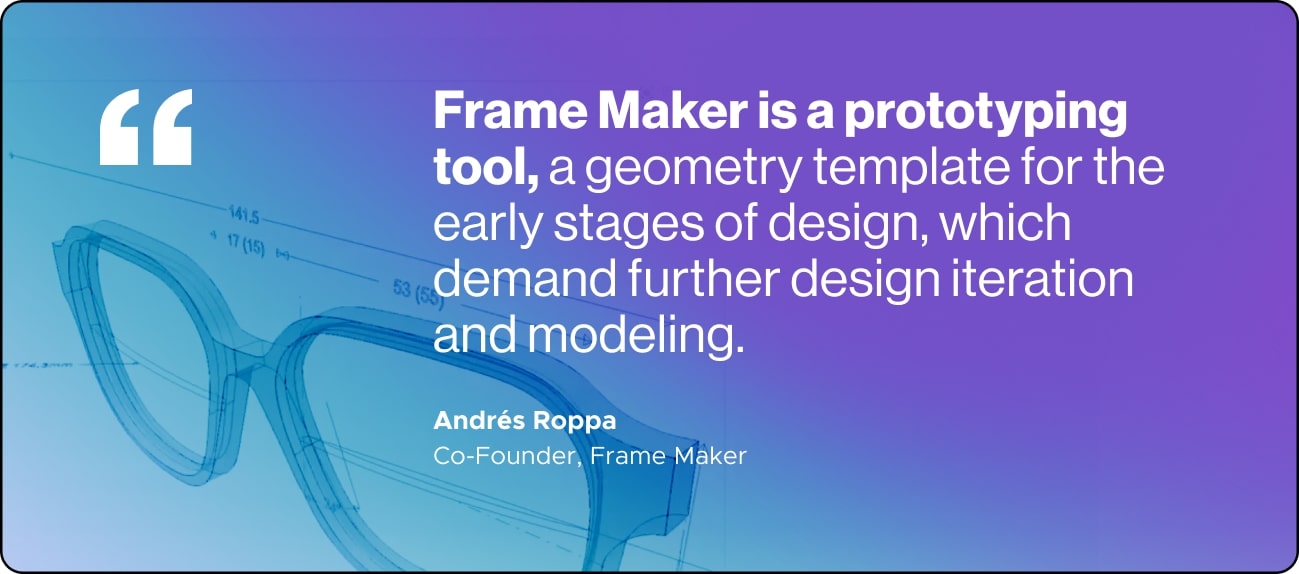

This is a complex topic. By trying to automate a design process for a product with such an artistic intent, you are always on the edge of oversimplification. This can lead to everything seeming alike. This is why Frame Maker is a prototyping tool, a geometry template for the early stages of design, which demand further design iteration and modeling.

My custom client projects are more complex because they are not just basic geometry; they require a specific brand aesthetic to be kept.

4. Can you describe how Frame Maker simplifies the process of generating 3D frame models from the designer’s perspective?

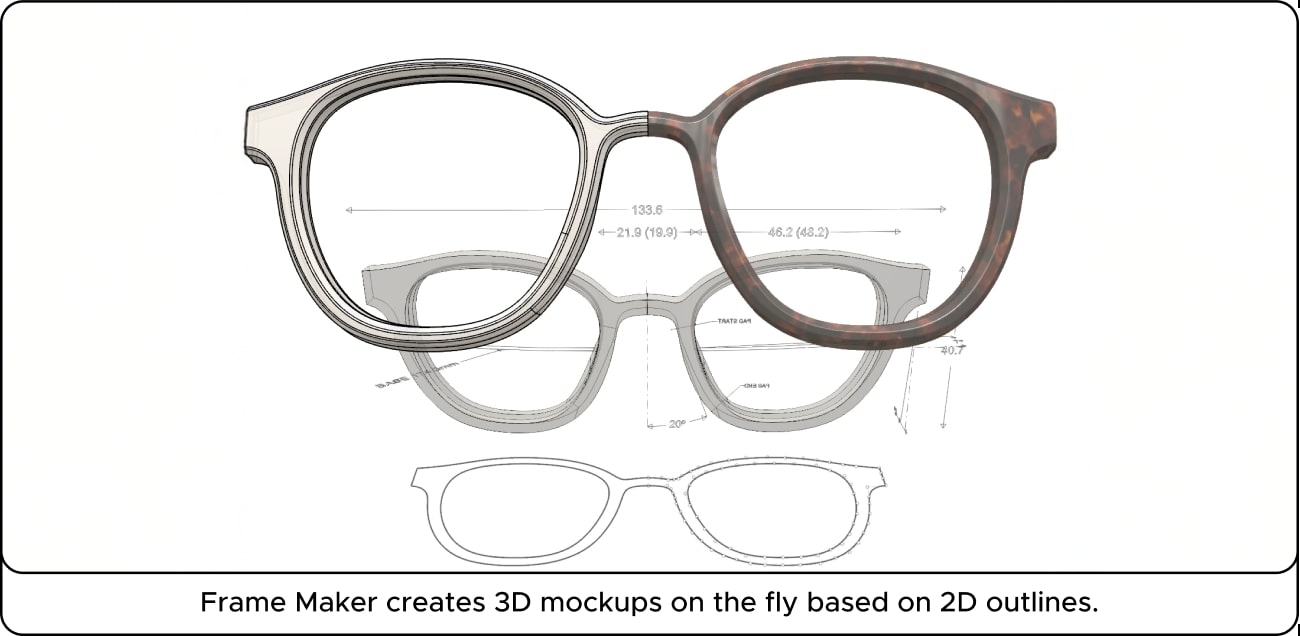

The idea behind Frame Maker is to automate the mechanical or repetitive parts of the modeling process. It creates a 3D mock-up (printed or virtual) on the fly, based on 2D outlines, which is the usual design approach within the industry.

5. What were the most complex technical hurdles when developing Frame Maker, especially around handling diverse 2D input styles?

The biggest challenge was creating a Grasshopper script that would be versatile enough to achieve the desired 3D frame geometry, parting from curves with different drawing techniques. This means addressing point distribution, drawing errors, overlapping curves, etc. I came up with simple methods for discarding or subtly adapting geometry that would “break” the workflow.

After that was working satisfactorily, I could start adding other frame features, such as changing size, thickness, or adding features like nose pads. My goal was to avoid plugins as much as possible and rely on Grasshopper's native components. I learned a lot from this process. Now it’s time to revisit the entire script and organize.

6. How do you decide what level of customization to automate versus leaving creative freedom to the designer?

Based on conversations with experienced designers about their process and needs, I decided to develop and market Frame Maker as a prototyping tool to create accurate CAD files for prototyping during the early stages of design. From that point on, the variation in each design is infinite and would be impossible to manage. This was the key trade-off decision if I wanted to deliver a consistent 3D model for the brand or designer to download and continue working on. Trying to automate too much would be less flexible and hinder any further creative process by the designer.

7. ShapeDiver allows you to distribute Frame Maker without requiring Rhino or Grasshopper knowledge. How did that shift your strategy in terms of accessibility and scalability?

ShapeDiver opened the door to a wider design audience, not just the 3D modeling experts. I tried to see it from the perspective of a designer using 2D only, building the 3D model in simple steps that could be easily understood. I know that acetate manufacturing design and techniques are most common, so this became my primary reference.

8. Which ShapeDiver features have had the biggest impact on your users — and are there specific updates or tools you’re excited to integrate next?

App Builder for sure, as it makes the interface so friendly, and it forces me to rethink how to integrate new features and make them as user-friendly as possible. I also see a lot of potential in saving model states that the user can come back to and continue editing.

9. Vision Now sounds like a fascinating example of tailoring parametric tools to a brand’s specific needs. Can you walk us through the collaboration process — from understanding their requirements to deploying the final app?

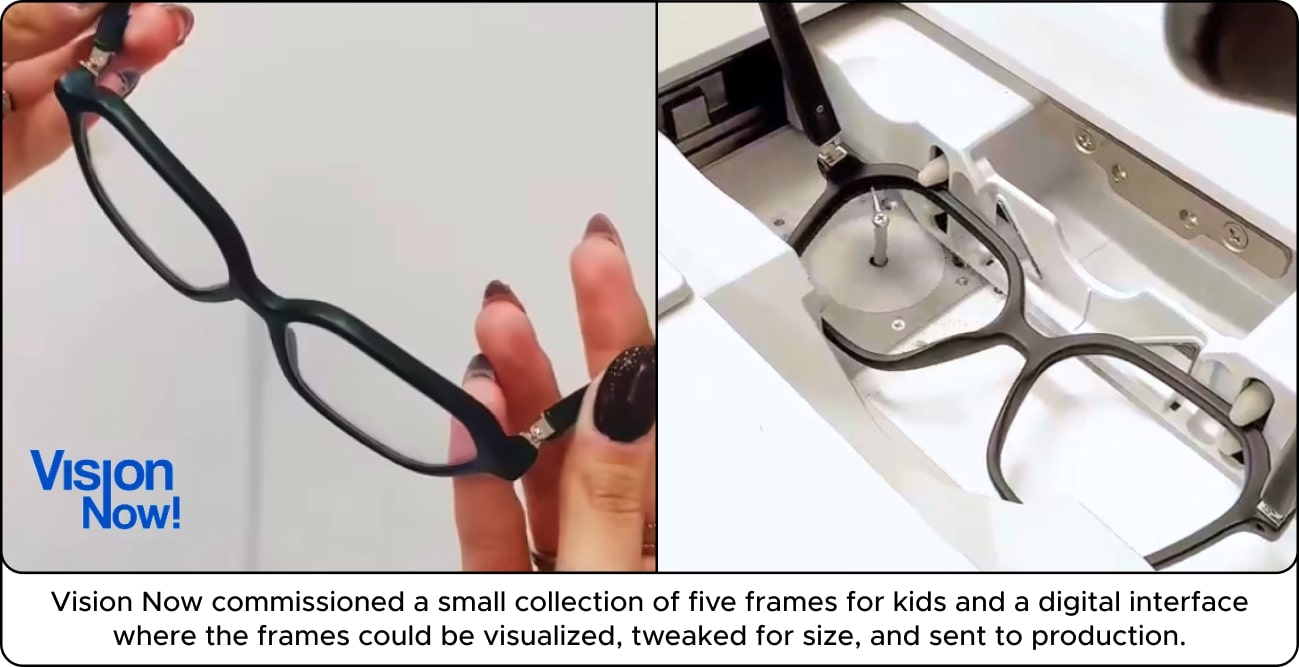

When I was first approached by Vision Now, they already understood that 3D printing could be the ideal production method to complement their frame inventory in specific ways. This is crucial because they had a clear direction and knew how it would impact their business.

Together, we arrived at a proper solution involving a small collection of five frames for kids and a digital interface where the frames could be visualized, tweaked for size, and sent to production. This is an attractive offer, different from the traditional products in the store. Moreover, it’s a flexible solution that can be easily adapted to suit different opportunities, such as replacing styles that don’t sell with new ones by updating the digital stock inside the application. Since the collection is parametric, introducing new styles is quite quick. In terms of production, VN had already decided on the Genera G1/F1 3D printer. The workflow was now established.

Vision Now was new to 3D printing, so setting up the print files and post-processing the frames would surely be a challenge. In view of this, I proposed a geometry optimized for the G1/F1, thanks to previous experience with the material. I also proposed a hinge model that is quick and easy to install.

At this point, prototypes were made, along with tweaks and iterations to achieve a proper hinge fit and refine surface features. With approval from VN on the frame results and assembly, I developed the parametric tool with all five models. With access to the tool on the App Builder interface, it’s now time for testing in the store. Kicking off takes time and adjustment, but once this system is running, the app can be replicated in their other stores, centralizing production in the original one.

10. How does Frame-Stock balance between developing universal tools like Frame Maker and bespoke solutions for brands?

Frame Maker is an ongoing project. It demands a lot of attention when introducing something new or addressing user feedback, which usually generates a version update. My custom client projects are challenges that arise as a brand understands the business potential of leveraging parametric designs that are exclusive to them. Some of these projects are not related to eyewear.

11. Do you see a future where most eyewear design and production happens through parametric systems and in-store customization like Vision Now?

It will certainly play a big role. Parametric systems can be implemented differently, depending on the business goal, product, and manufacturing method. So I see a range of possible parametric solutions, where some may take the stage in the store experience, while others may choose to focus on customization and production in the shop's “back end” only.

12. How might emerging technologies — AI design assistants, 3D scanning, or new materials — intersect with your current workflow?

3D scanning is already common with footwear, and there are similar projects for frames. I am not pursuing that direction for now, but it’s another path to customization. New materials already influence how I develop a certain solution. I constantly test new 3D technologies, collaborating with hardware providers to create optimized collections for those specific requirements. Materials and technologies are becoming increasingly diverse, with options growing and quality improving for consumer-ready prints.

Finally, conceptualization and idea generation with AI assistants is amazing. I’m still catching up and learning how it might best integrate with my work. My current focus is on delivering CAD files in a controlled or predictable manner, 2D to 3D, but I’m sure that AI will inevitably play a part at some point.

13. Looking ahead, what’s your long-term vision for Frame-Stock? A design studio, a software platform, or a bridge between both worlds?

That’s a big vision question that I am currently working on. A mix of things is the most likely answer. As an independent, I have always been used to pivoting and changing directions with my work. Developing a serious software platform would require absolute full focus and another level of investment. I developed Frame Maker as an industrial designer, not as a software developer. A design studio? mmm not sure … I’ll leave this one open.

- This has been great. Thank you very much for your time, Andrés!

Thank you as well for this opportunity to share what I'm doing with ShapeDiver.

That's it for this new edition of Getting to know... Don't forget to visit the Frame-Stock website!

Would you like to get featured in this space? Please email us at contact@shapediver.com and tell us about your project or brand! We'd love to start a conversation.