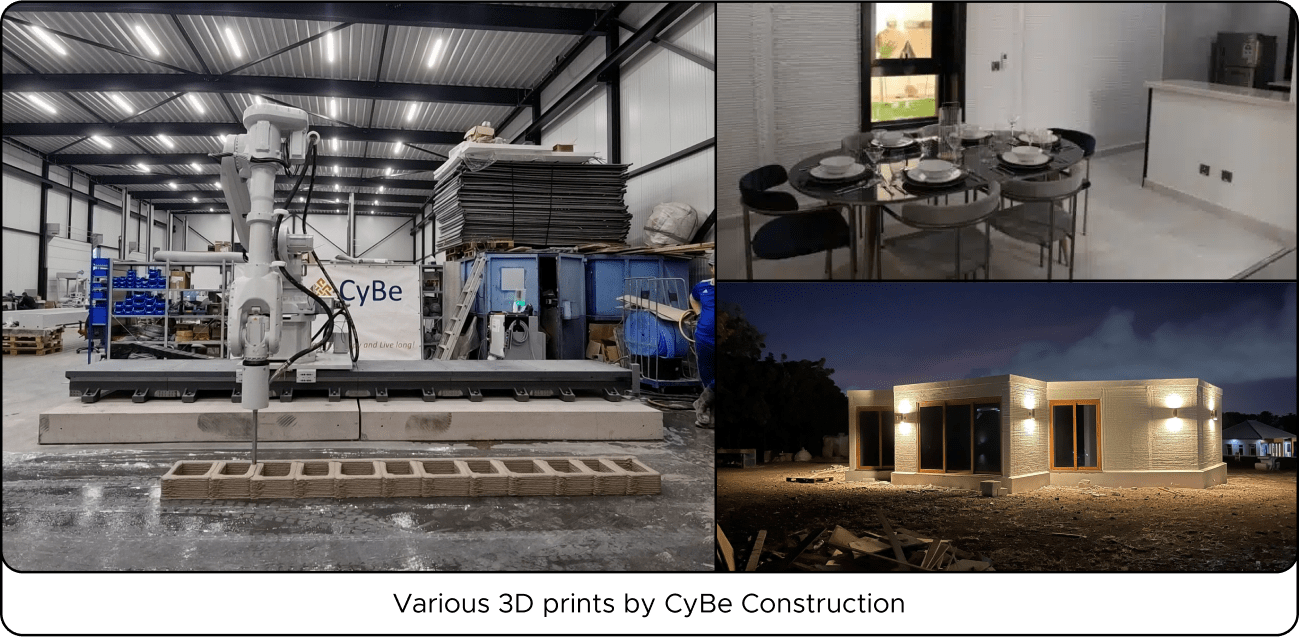

In this interview, we talk with CyBe, a Dutch technology company revolutionizing the construction industry with its state-of-the-art 3D concrete printing technology. We explore how they use this technology to create affordable housing while reducing the carbon footprint of their projects.

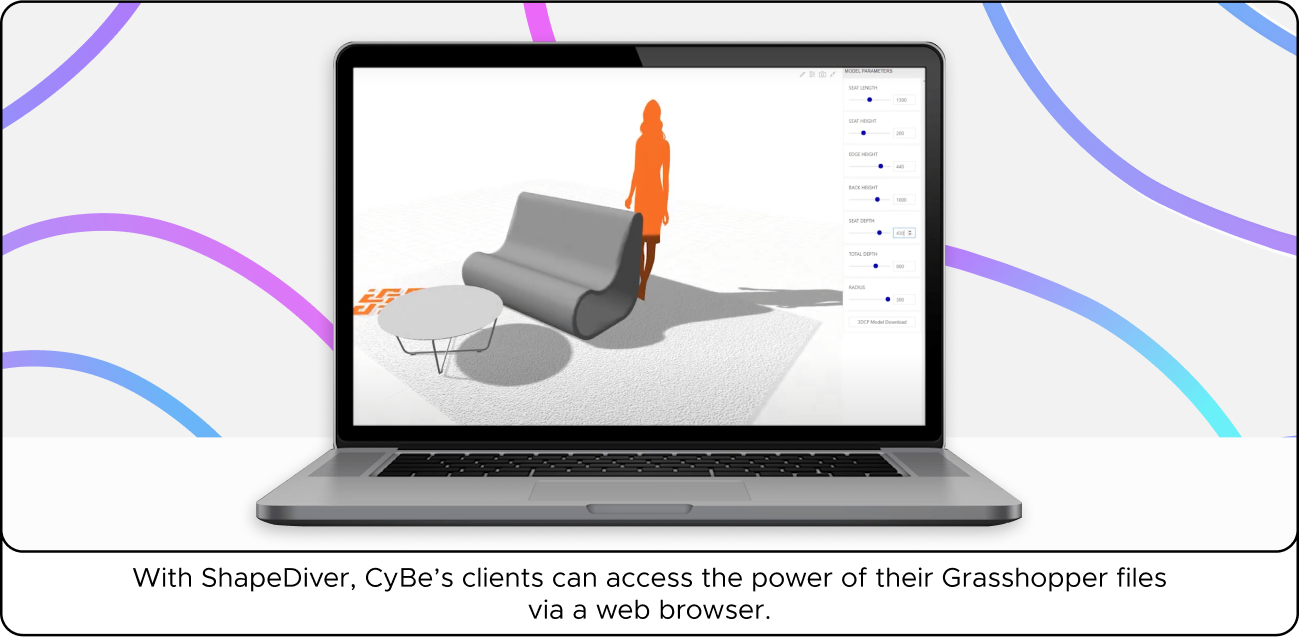

You'll also learn about the different types of printers they offer and how their proprietary software tools streamline the printing process. We also dive into how they're using Grasshopper and ShapeDiver to create online configurators that any client can easily use.

1. Welcome, and thank you for taking the time to chat with us! Let’s start with the basics. Who is CyBe?

Thank you for having us here. Sure! CyBe is a technology company for the construction industry with an emphasis on process innovation and social prosperity. We mainly sell 3D concrete printers worldwide and are the leading 3D printing contractor in the Netherlands.

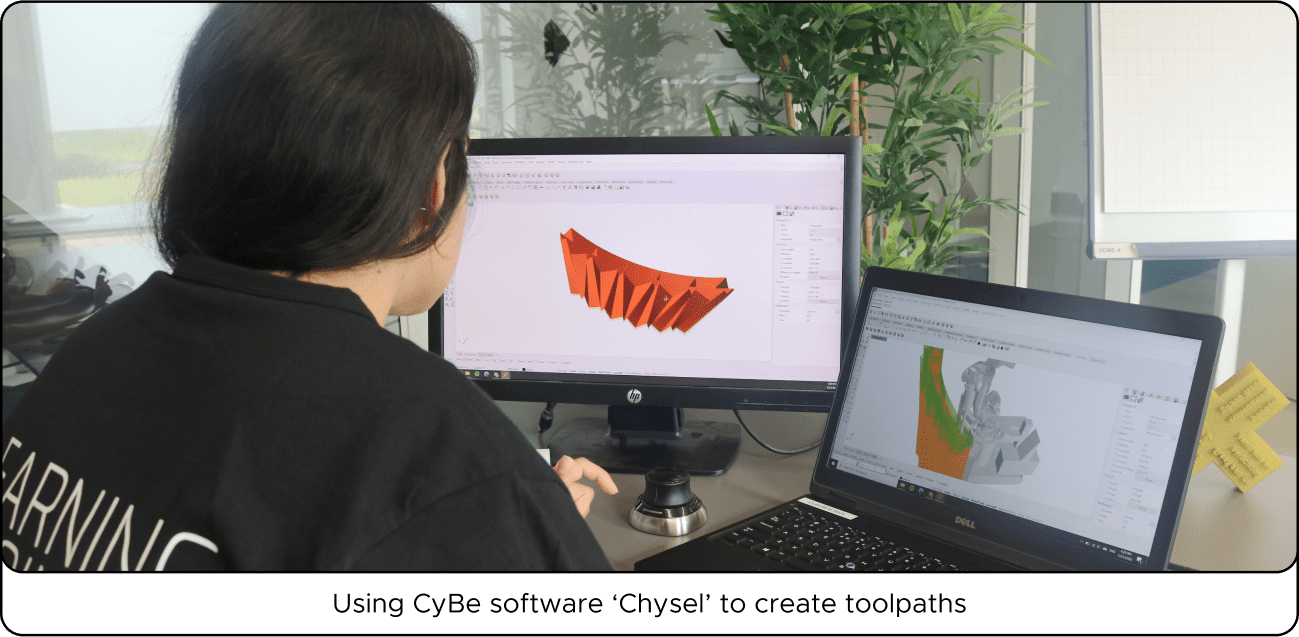

In addition to 3D concrete printers, we produce high-quality proprietary tools, including our slicing software Chysel and Artysan, to operate the printer, CyBe Mortar, and the CyBe Lybrary learning platform. We also develop custom printing materials and parametric design software tools to ensure that our printers operate at the highest efficiency possible.

Our holistic building solution draws from the full range of construction expertise and enables sustainable growth for individuals and businesses alike.

Our mission is to create a better society. That begins with homes and other built structures and extends to a community’s natural environment and socioeconomic opportunities. It is founded on our affordable and sustainable approach to construction and home ownership, which offers long-term security to an increasingly broader range of citizens worldwide.

Our efforts begin with how we build. We invest heavily in research and development and use advanced tools and technologies emphasizing quality performance and outcome.

This unique combination of technologically advanced hardware, software, and materials is essential to achieving our overarching goal: to empower our construction partners and customers to enact sustainable business models and to bring global citizens the opportunity for affordable housing and rightful human dignity.

2. That’s great. We’ll touch on affordable housing in a bit. Before we do that, could you explain what 3D Concrete Printing is? What are its core benefits?

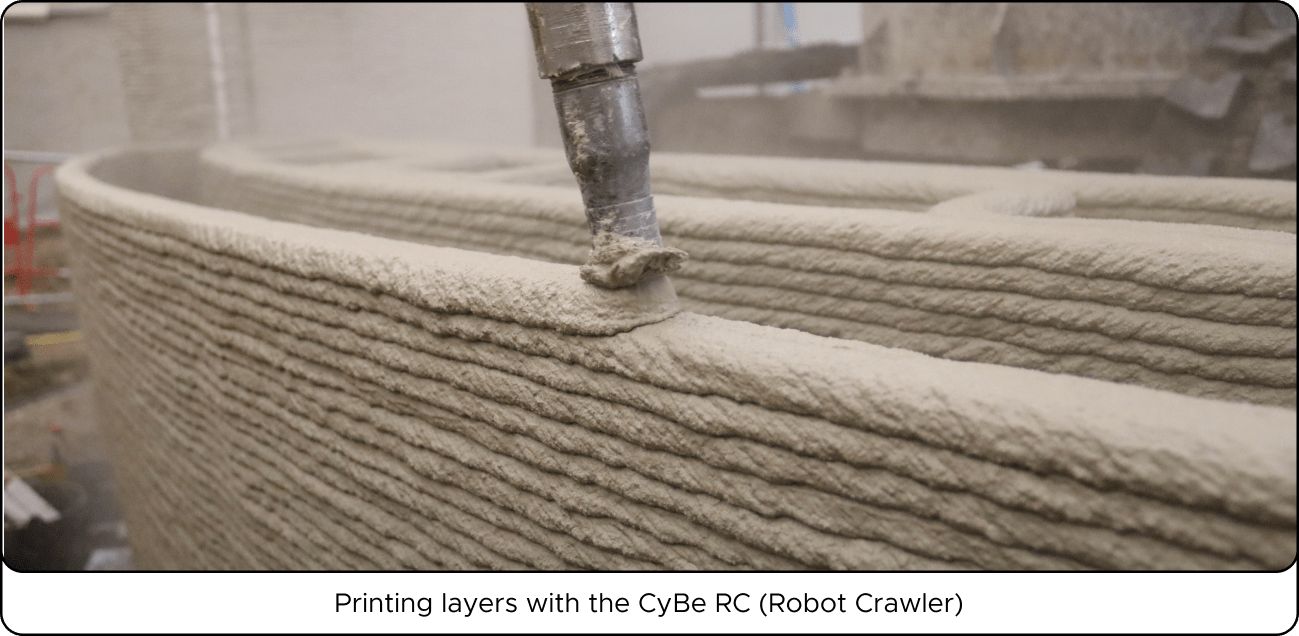

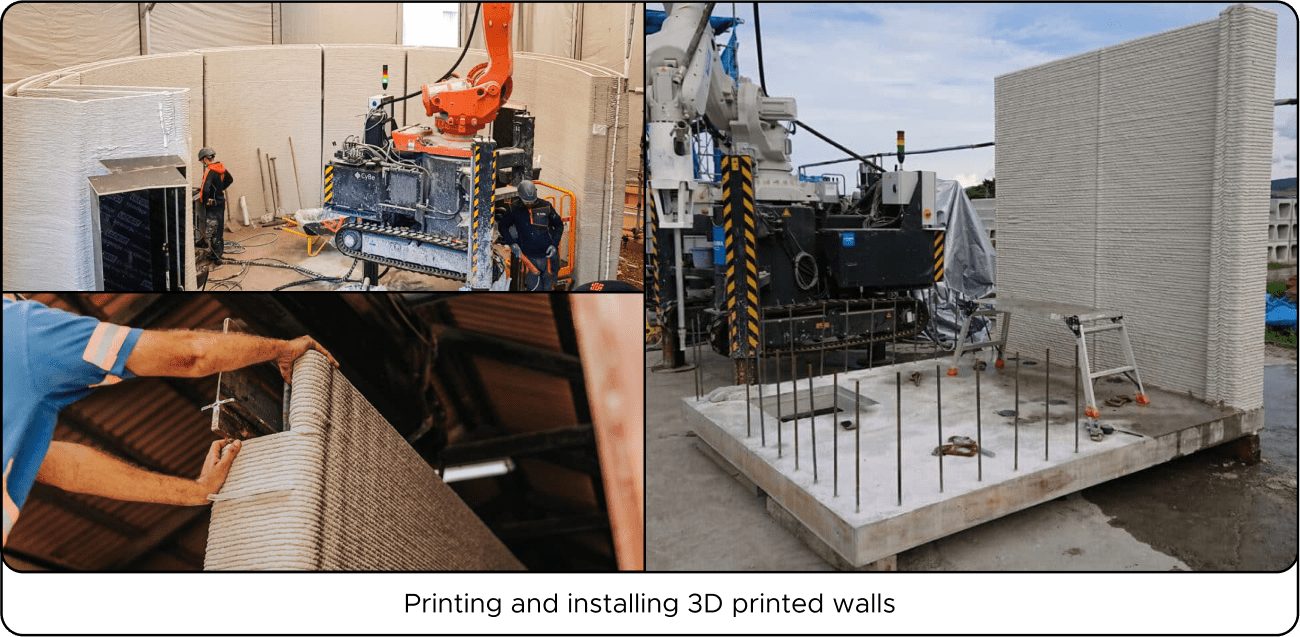

3D concrete printing is a process that involves depositing layers of material, typically a mixture of concrete and other additives, one on top of the other, to create three-dimensional objects.

It’s an efficient method of building that minimizes materials and labor costs and maximizes production. 3D concrete printers bring incredible value to the construction industry, particularly in a housing shortage period.

3. Why is this manufacturing process so crucial for CyBe?

Technology and, therefore, these manufacturing processes are just a means to an end. Consequently, it is crucial to CyBe because it allows affordable housing to be delivered faster and more sustainable with Co2-poor cementitious materials and soon even Co2-free. This is a significant advantage for addressing the global housing crisis.

4. Which regions are your primary target markets?

We sell printers worldwide, and we have partners in every continent (except for Antarctica). Our partners focus on building faster and cheaper and are mostly innovative companies. In addition, our partners are also research institutions, such as universities.

5. Can you expand your comment on the current worldwide housing shortage? How is CyBe positioning itself to tackle this problem?

Costs of homes are rising. Rents are rising. The number of low-income housing units is decreasing. Around the world, around four billion people lack access to decent housing, including 150 million in developed countries, and more than 800 million live in slums.

To meet this requirement, CyBe is focusing on innovation to offer 3D concrete printing as an innovative, affordable housing solution. This enables cheaper, faster, and more sustainable construction.

6. What does “Affordable Housing” mean for CyBe?

For CyBe, affordable housing means creating housing solutions for low-income populations so they can gain access to housing at the most affordable price. Affordable housing is a business activity with a major social impact. We offer a wide range of innovative building solutions tailored to the local challenges and needs of individuals, NGOs, and public organizations responsible for housing.

7. That’s a great purpose! Let’s jump back to your products. What types of 3D Concrete Printers do you offer, and what are their main characteristics?

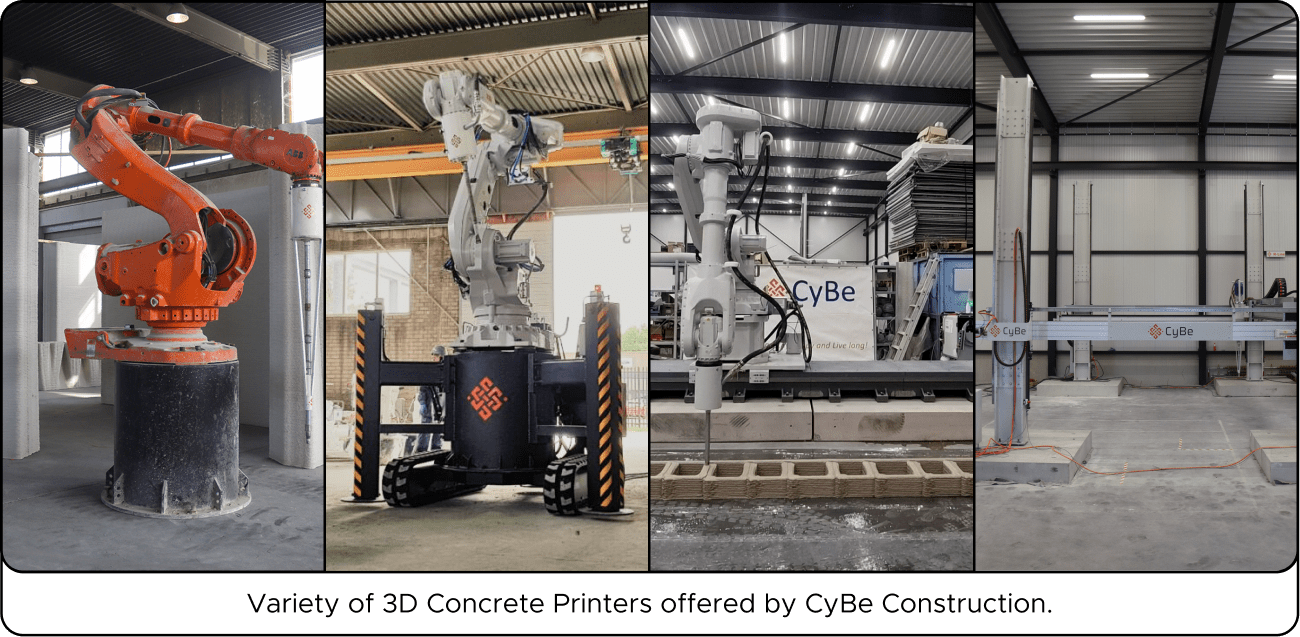

We offer five different types of printers. These range from robotic arms to gantry systems.

- The CyBe R

is an entry-level fixed 3D concrete printer ideal for research institutes, universities, and suppliers performing in-house testing, prototyping, or precast production.

- The CyBe RC is a mobile 3D concrete printer suitable for construction companies printing on-site or in precast factories.

- The CyBe RT is a 3D printer that moves across a stationary track setup and is suitable for precast factories building prefab homes.

- The CyBe G is a 3D concrete printer that can print anywhere within an established three-dimensional zone and is best suited for printing large modules in a factory setting, such as finished apartments.

- The CyBe GR is similar to the CyBe G but has a robot attached to the X-beam for a wider and more precise range.

All printers use an ABB robotic arm and an ABB-controlled printhead and nozzle for printing. The printers vary in their mobility, stability, and printable height, making them suitable for different applications, from research and prototyping to on-site construction and precast production.

8. What type of projects do your clients build with 3D Concrete Printers, and what advantages have they seen?

We are receiving a wide variety of inquiries, from furniture to planters to 4-story apartment buildings. Sometimes clients will approach us with a design we need to engineer to make it printable, while others will ask us to design from scratch.

Either way or any scale that can be required, our clients will benefit in terms of time, cost, more sustainable solutions, less waste during construction, and more flexibility and potential on the design that cannot be achieved with conventional construction in an equally efficient way.

9. Grasshopper has become an integral part of CyBe’s design team. When was Grasshopper first introduced inside the company, and why?

We have used Rhino and Grasshopper since 2013. Our “Design & Engineering” team uses Grasshopper to develop several tools and projects. Parametric Design was introduced during the technical/operational phase of projects since it is important to automate several procedures regarding designing for printing and printability checks.

Grasshopper is also a powerful tool during the conceptual phase when the team needs to design more complex geometries with repetitive structures or develop wall textures that can be applied to multiple surfaces.

Later, we came up with the idea of letting our clients adjust our designs according to their preferences. Therefore, creating a layout that could be easily used by any person, relevant to Grasshopper or not, was crucial for our company.

10. How is Parametric Design influencing the way CyBe tackles new projects?

There are many advantages to using parametric design when constructing a building. One major reason to use parametric design is to save time in the design process.

The early design phase is a fluid, exploratory process in which design concepts and drawings are built up at the same time. This eventually leads to a blueprint, a 3D model visualization, and data documentation about the design.

But changes or adjustments are inevitable, and that’s why parametric design is so efficient. Unlike traditional design methods, parametric design uses algorithms to implement the impact of one adjusted component on an entire design.

Existing designs can be easily altered or customized for new client projects using parametric design. This means less time is spent on the initial design phase, and customization can be fast and easy. This is particularly useful in housing development projects where a standard template can be adjusted to serve different client needs and create varied aesthetics.

Every new project is unique and different. Nonetheless, some general variables such as room functions, construction principles, codes, and 3D printing guidelines have to be always met. Instead of going through this rationalization phase with every new project, we can create dynamic housing concepts where their feasibility is already considered. Then, we can allow our partners and customers to explore their ideas and make decisions through their input while generating realizable and efficient designs that meet their unique needs.

11. How is ShapeDiver helping you reach your goals?

ShapeDiver has become a very powerful tool, especially for creating online configurators that can be reached and used by any possible client. We have already implemented ShapeDiver on both our websites, Lybrary and Lyve. The simplicity of the grasshopper implementation, the minimal layout, the control we can have on the parameters, and the adaptability with many plugins are only a few characteristics that benefit our time and improve our workflow.

12. That’s great to hear! Finally, what’s the future of 3D Concrete Printing?

Several limitations still need to be overcome in 3D concrete printing construction. Our company makes significant steps to address those, develop new concepts in terms of printers and printable elements, and constantly increase capabilities.

We are currently achieving the first 3D-printed 4-story building, and we anticipate reaching even higher goals in the upcoming years!

- That sounds like a great and ambitious project! Thank you for taking the time to talk to us today and share more about your company.

Thank you for having us here. To all the readers, please visit our website for more information: https://cybe.eu/3d-concrete-printing/printers/.

That's it for this new edition of Getting to know... Don't forget to visit their website and LinkedIn profile to learn more about their company.

Would you like to get featured in this space? Please email us at contact@shapediver.com and tell us about your project or brand! We'd love to start a conversation.